XCMG Official Manufacturer TZ2S Double-boom hydraulic pilot drill jambo

Summary

- Transport Dimension(L*W*H):14400×2550×3126 mm

- Weight:32000 kg

- Model Number: TZ2S

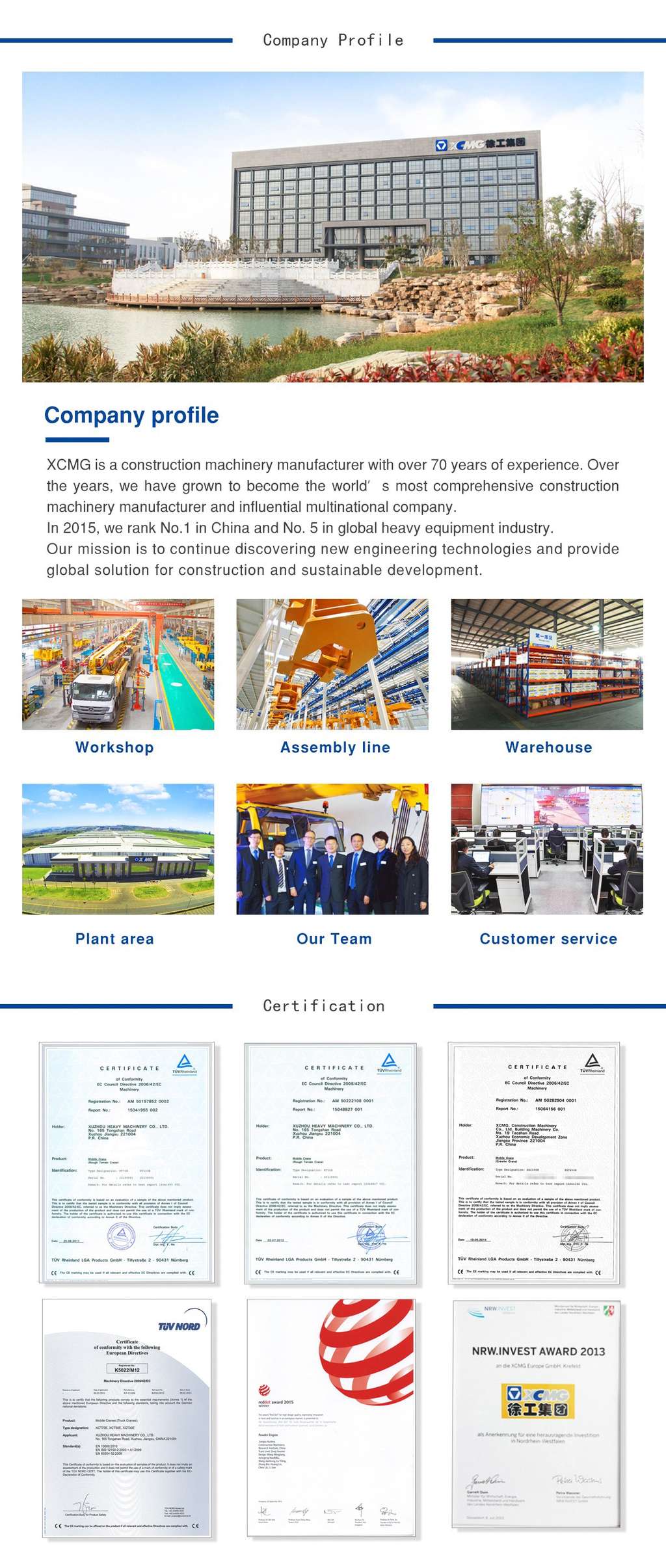

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:32000.000kg

- Condition:New

- Moving Type:Wheel

- Maximum operating cover area:104 m²

- Maximum operating height:9200 mm

- Maximum operating width:13600 mm

- Drill boom extended length:1600 mm

- Drill boom lifting angle:(65/-30)°

- Tilt angle for propeller:±45°

- Propeller tilt angle:360°

- Propeller compensation length:1800 mm

- Maximum propulsive force:20 kN

- Drill hole depth:3398/4003/4613/5217 mm

- Gadder Model:HC109/HC110(optional)

- Impact power of gadder:18.8 kW(HC109)/31 kW(HC110)

- Impact frequency of gadder:40—50 Hz(HC109)/62—77 Hz(HC110)

- Swing torque of gadder:780 N.m(HC109)/557 N.m(HC110)

- Diameter for dill hole:Φ43—Φ102 mm

- Water flushing pressure:10—15 bar

- Gas lubrication pressure:2—4 bar

- Work service platform:Optional

- Lifting height for work service platform:9000 mm

- Swing width for work service platform:—

- Rated load for work service platform:401 kg

- Lifting height of cab:—

- Lifting height of cab roof:—

- Total installed power:170 kW(HC109)/215 kW(HC110)

- External power supply:380/50 V/Hz

- Maximum traveling speed:16 km/h

- Maximum gradability:14°

- Engine power:119 kW

- Transport dimension:14400×2550×3126 mm

- Curb weight:32000 kg

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

TZ2S Double-Boom HydraulicPilot Drill Jambo

TZ2S Double-Boom HydraulicPilot Drill Jambo

1、Main Applications

It’smainly applicable for the tunneling operations of roadways and tunnels in minesand other underground projects.

Capableof drilling of blast holes, anchor rod holes, and undermining holes andinstallation of explosives, anchor rods, and air ducts.

Maximumoperation area coverage:104㎡.

2、Technical Features

(1)Drill jambo

Thehydraulic drill jambo adopts special structural process on the basis of thedomestic tunneling process to realize super-strong anti-bending capability,high drilling speed, and low drilling tool consumption and effectively improvethe working performance of tunnel side hole drilling.

(2)Propeller

Thelightweight high-strength alloy girder features high anti-bending,anti-distortion, and anti-fatigue performances and longer life.

(3)Chassis

It’sapplied with energy-saving, environmental-friendly, and low emission engine,powerful all-road all-drive self-adaptive traveling system, integral frame, andrear-wheel steering system, featuring high vehicle stability.

(4)Drill boom

Theall-directional paralleling-maintained drill booms of proprietary technologyfeatures accurate positioning. The drill booms adopt equal-strength structuredesign to realize reasonable structure, high strength, and long life.

(5)Drilling system

The three-stage anti-seizure,anti-empty-drilling, and automatic return functions of drilling tool areprovided to effectively improve the drilling efficiency and reduce theconsumption of drilling tool.

(6)Centralized lubrication system

Thedistributor is applied to gather the difficultly accessible lubricating pointsto reduce the maintenance works.

(7)Hydraulic system

Theelectronic control design is applied for the auxiliary motions, includingoutriggers and roof lamp to simplify the pipelines and ease the maintenances.

(8)Electric system

The electric parts of world’s renowned brands,including Schneider, Siemens, Phoenix, Littelfuse, and Williams, are applied torealize high reliability and long service life. The production and warningfunctions, including grounding malfunction protection, phase sequenceprotection, digital current/voltage indicator, drill jambo impact timer, oilreturn filter blockage warning, motor thermistor protection, motor overloadprotection, engine malfunction warning, and transmission malfunction warning,are provided.

|

Item |

Unit |

Parameter |

|

Maximum operation cover area |

㎡ |

104 |

|

Maximum operation height |

mm |

9200 |

|

Maximum operation width |

mm |

13600 |

|

Drill boom extended length |

mm |

1600 |

|

Drill boom lifting angle |

° |

65/-30 |

|

Tit angle for propeller |

° |

±45 |

|

Propeller tit angle |

° |

360 |

|

Propeller compensation length |

mm |

1800 |

|

Maximum propulsive force |

kN |

20 |

|

Drill hole depth |

mm |

5217 |

|

Impact power of gadder |

kW |

31 |

|

Impact frequency of gadder |

Hz |

62-77 |

|

Swing torque of gadder |

N.m |

557 |

|

Diameter for dill hole |

mm |

φ43-φ102 |

|

Water flushing pressure |

bar |

10-15 |

|

Gas lubrication pressure |

bar |

2-4 |

|

Lifting height for working service platform |

mm |

9000 |

|

Rated load for working service platform |

kg |

400 |

|

Total installed power |

kW |

215 |

|

External power supply |

V/Hz |

380/50 |

|

Maximum traveling speed |

km/h |

16 |

|

Maximum gradability |

° |

14 |

|

Engine power |

kW |

119 |

|

Transport dimension |

mm |

14400*2550*3126 |

|

Curb weight |

kg |

32000 |