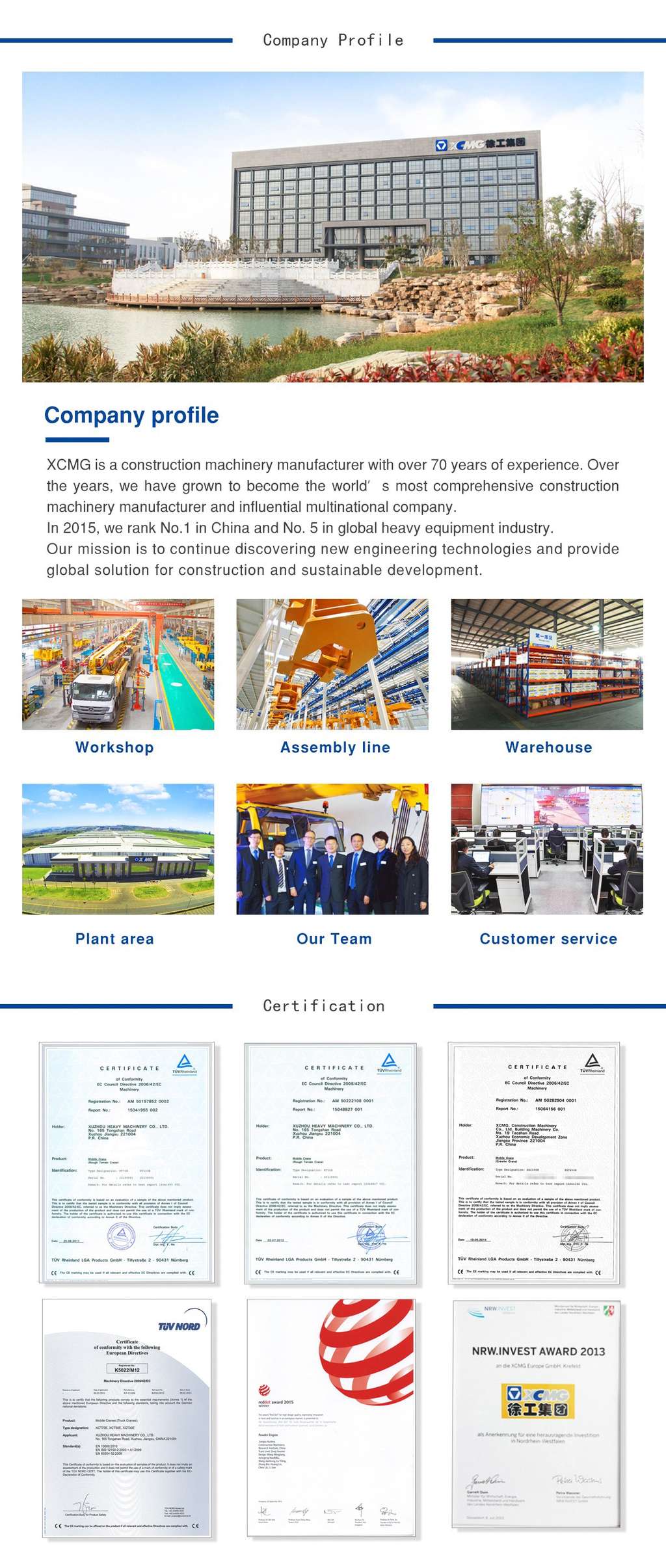

XCMG Official Manufacturer 8 tons Road Sweeper XZJ5160TSLD5 for sale

Summary

- Overall Dimension(L*W*H):8115×2480×3010

- Weight:15800 kg

- Model Number: XZJ5160TSLD5

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:15800.000kg

- Condition:New

- Moving Type:Wheel

- Chassis Model:DFL1160BX1V(stateⅤ)

- Chassis Power:155 kw

- Chassis engine model:—

- Wheelbase:4500 mm

- Total Mass:15800 kg

- Curb Mass:10300 kg

- Model of Auxiliary Engine:QSB5.9-C160-30(state Ⅲ)

- Power of Auxiliary Engine:118kw/2500r/min

- Suction diameter:250 mm

- Ground clearance during working:5~10 mm

- Operating speed:3~30 km/h

- Max Operation Width:3.5 m

- Sweeping Efficiency:—

- Max. sweeping capacity:105000 m²/h

- Sweeping and washing diameter:120 mm

- Max. Inhaled Particles:Φ900 mm

- Dustbin Volume:8 m³

- The Tank Volume:3 m³

- Lifting Angle:45°+10°

- Max. driving speed:98 km/h

- Max. climbing angle:30%

- Brake distance (full loading 30km/h):≤10 m

- Min. turning diameter:≤19 m

- Front/Rear wheel track:1880/1860 mm

- Approach angle:20°

- Departure angle:13°

- Min. ground clearance:150 mm

- Overflow pressure:14 Mpa

- Hydraulic oil volume:100 L

- Voltage of trailer chassis system:24 V

- Voltage of working units:24 V

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

XZJ5160TSLD5

Road Sweeper

XZJ5160TSLD5

Road Sweeper

1、Beautiful and practical model

of tank

On the premise of

meeting relevant use and strength requirements, it is integrally made of SUS304

single-layer stainless steel. It is simple and practical, with good usability.

Moreover, the dustbin is integrated with the fresh water tank, increasing the water

volume and making it convenient for batch production and processing. At the

same time, the lifting angle is increased for the dustbin, making it convenient

for garbage dumping. A dismountable structure is adopted for the sucker in the

tank. After it is worn, the sucker can be conveniently replaced.

2、Sweeping mechanism under self-adaptive control

The mode of spring

adjustment is adopted for the ground pressure of side sweeper system. In the

working process, the ground pressure of the sweeper can be adjusted at any time

according to the pavement condition, so as to reduce wear of the sweeper. In

order to reduce wear of the sweeper, the mode of spring adjustment is adopted

for the ground pressure of side sweeper system. Its ground pressure can be adjusted

at any time during working according to the pavement condition. In order to

solve the issue of sweeping plate obstacle, one end of the oil cylinder support

is connected via shackle, making the oil cylinder under a floating state. When

the sweeping plate encounters an obstacle, the function of automatic avoidance

can be realized.

3、Efficient air duct system

The air duct system

serves as the basis for the pneumatic transmission system of the cleaning

sweeper truck. It includes the following three parts: suction nozzle, tank

pipeline and fan, which decides the garbage suction force, airflow loss and

system power. At the same time, it is also a key design part of the sweeping

machine.

(1)Efficient

sucking disc

A total floating suction

nozzle structure of narrow suction nozzle + single large air duct is adopted

for this machine. A roll sweeping device is added to the rear end of the

suction nozzle, which is driven by motor, effectively improving the sweeping

efficiency and speed. During working, the motor speed is adjustable, or the

motor may not work, so as to adapt to different pavement conditions.

(2)Efficient

centrifugal fan

The independently

researched and developed centrifugal fan is adopted, with the maximum blast

capacity of 12,000m3/h. The fan has large total pressure and high

efficiency. Its blade is made of special steel. The special shape of its blade

is extremely uneasy to wear.

4、Reliable and effective dust falling system

The stainless steel

water spraying frame of sweeping plate is equipped with a low-pressure

fan-shaped nozzle, in order to suppress the dust raised by the sweeper.

Furthermore, a dust reduction spray pipe is also installed at the suction

nozzle. A self-made large-diameter nozzle is installed, so as to suppress the

dust raised when the sweeping plate absorbs garbage. Wenzhou Hanxing

centrifugal water pump shall be selected as the water spray pump, which is

provided with an electromagnetic clutch. At the same time, a water torch is

provided as well, making it convenient for integral cleaning, maintenance and

high-pressure washing at the fixed point.

5、Convenient PTO port

Commons

QSB5.9-C160-30 is adopted for the auxiliary engine. The hydraulic pump is

directly driven by the auxiliary engine through the side force taking port (PTO

port), which improves the transmission efficiency, reduces the transition of

supporting seat, saves oil consumption, lowers the user costs, and effectively

lowers the failure rate.

6、Power output system

The output

protection device of clutch for vehicle + air cylinder control is adopted for

the auxiliary engine of sweeping machine, which guarantees no-load starting and

no-load shutdown of the auxiliary engine, solves the issue of large output

impact of the engine, and gives better protection to the engine, fan and

high-pressure water pump.

7、 Intelligent control system

(1)Integrated

control mode

The mode of relay

control is adopted. The control circuit is simplified. Many logic protection

functions can be realized. Most elements are foreign brands, with a low failure

rate. It is fast and convenient for replacement. Moreover, the maintenance difficulty

is also reduced.

(2)Multiple

safety protection

A variety of protection

devices are provided, including voice alarm protection, voice avoidance

reminder, voice fault alarm, fresh water tank low level, dustbin high level,

hydraulic oil tank low level, dustbin rear door non-opening and non-laid-down

safety support.

8、Safe and reliable hydraulic system

Dual-power hydraulic

element system is adopted, which is driven by the chassis and the auxiliary

engine. The chassis and the auxiliary engine can be used for unloading and

lifting of suction nozzle and sweeping plate. In the process of unloading, it

only needs to start the chassis engine. It is unnecessary to start the

auxiliary engine. Thus, it reduces the start-up time of auxiliary engine,

lengthens the engine service life, and saves fuel oil as well.

A hydraulic system with

three independent valve blocks is adopted, free from mutual inference and

convenient for maintenance.

9、A kind of mixed-material highly wear-proof

sweeping technology

The brushing formula

with good frictional wear performance was independently designed and developed

by adjusting the proportion of PP & PE raw material, inorganic filler and

their auxiliaries. Meanwhile, the performance of various test recipes was

detected. On this basis, the nylon matrix brush exclusive for XCMG was

researched. The service life is improved by 2 times.

|

Items |

Contents |

XZJ5160TSLD5 |

|

|

Chassis Parameters |

Model |

DFL1160BX1V(StateⅤ) |

|

|

Power |

155kW |

||

|

Wheelbase |

4500mm |

||

|

Auxiliary Engine |

Model |

QSB5.9-C160-30(StateⅢ) |

|

|

Power |

118kw/2500r/min |

||

|

The Vehicle

Parameters |

Total Mass |

15800kg |

|

|

Overall Dimension |

8115×2480×3010,3255mm |

||

|

Curb Weight |

10300kg |

||

|

Dustbin Parameter |

Dustbin Volume |

8 m³ |

|

|

The Tank Volume |

3 m³ |

||

|

Lifting Angle |

45°+10° |

||

|

Suction Nozzle |

Suction Diameter |

250mm |

|

|

Working Ground

Clearance |

5~10mm |

||

|

Working Performance |

Road Sweeping Width |

3.5m |

|

|

Sweeping Speed |

3~30 km/h |

||

|

Max. Sweeping

Efficiency |

105000/h |

||

|

Max. Inhaled

Particles |

120mm |

||

|

Brush Diameter |

Φ900mm |

||

|

Driving performance |

Max. Speed |

98km/h |

|

|

Max. Climbing Angle |

30% |

||

|

Braking Length |

≤10m |

||

|

Min Turning

Diameter |

≤19m |

||

|

Structure size |

Wheelbase |

Front wheel |

1880mm |

|

Rear wheel |

1860mm |

||

|

Approach Angle |

20° |

||

|

Departure Angle |

13° |

||

|

Min. Ground

Clearance |

150mm |

||

|

Hydraulic System |

Overflow pressure |

14MPa |

|

|

Hydraulic oil

capacity |

100L |

||

|

Electrical System |

Chassis system

voltage |

24V |

|

|

Working device

system voltage |

24V |

||