XCMG Official RT70E Rough Terrain Crane for sale

Summary

- Model Number:RT70E

- Brand Name:XCMG

- Place of Origin:China

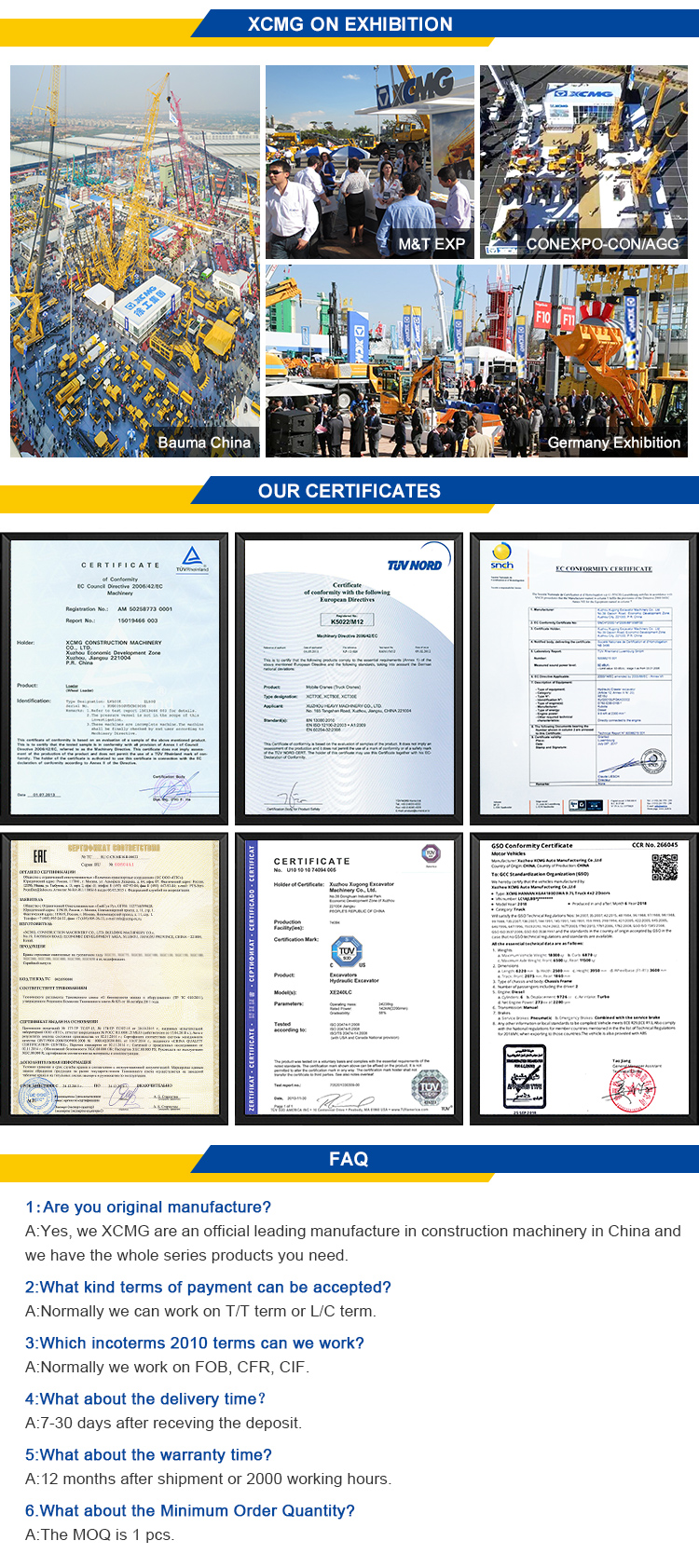

- Certification:CE/ISO9001

Specifications

- Weight:49000.000kg

- Condition:New

- Moving Type:Wheel

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

1、Specialized energy-saving hydraulic system.

2、Due to powerful power configuration, specific off-road tires and all-wheel drive, the crane can easily handle various tough terrains.

3、The crane is designed by conforming with the safety standards of Europe, North America and China, for optimal active protection.

4、Developed jointly by Chinese and German engineers, with advanced design concept.

5、Accumulation of experience in boom crane design for 70 years.

6、Top class modern plate machining center, and first class NC machining center.

|

Weight |

|||||

|

Axles |

1 |

2 |

Total weight |

||

|

kg |

25500 |

23500 |

49000 |

||

|

|

|||||

|

Hook block |

No.of sheaves |

Remarks |

|||

|

35t |

3 |

Single hook |

|||

|

|

|||||

|

Working speeds |

|||||

|

|

Km/h |

|

|||

|

29.5 R 25 |

35 |

65% |

|||

|

|

|||||

|

Mechanisms for operation |

Working speeds |

||||

|

|

0-130 m/min, no load, 4th layer, |

||||

|

|

0-130 m/min, no load, 4th layer |

||||

|

|

0-2 r/min |

||||

|

|

Approx. 80s for boom elevation from -1.5° to 80° |

||||

|

|

Approx. 120s for boom extension from 11.32m to 43.2m |

||||

|

XCMG——RT70E |

|||||

|

Technical specifications |

|

||||

|

Structural members |

Turntable and frame are made of fine grained high strengthsteel,with anti-torsionlarge cross-section frame structure, have heavy load-bearing capacity.

|

Boom |

1 basic boom and 4-telescoping sections, qua drilateral cross section welding structure. Double-cylinder plus ropes telescoping mech anism is for synchronous plus sequential tele scoping. 6 pulleys on boom head are standard. Boom length: 11.32m ~ 43.2m. |

||

|

Outriggers |

4 outriggers, H-shaped arrangement, which are controlled by hydraulic valves and cylinders that are controlled by electric signals and located at both sides of chassis frame. Front and rear towing eyes are available. |

Operator's cab |

Integrated design, appearance is simple and artistic. It is all-weather and equipped with large arc glass, which has a wide vision, as well as spacious and comfortable due to ergonomic inner design. |

||

|

Engine |

QSB6.7, in line six-cylinder water-cooled compression ignition diesel engine, manufac tured by Cummins, US, rated power 194kW/ 2200rpm, max. torque 987Nm / 1500rpm, off road U.S. EPA Tier 3/EU Stage IIIA emission standards. Fuel tank capacity : Approx. 300L |

Safetydevices |

Hydraulic balance valve, hydraulic relief devices valve, hydraulic double-way valve and Lowering limiter is equipped in winch to prevent rope over-releasing. Anti-two block is fitted on the boom head to prevent rope over winding.

|

||

|

Hydraulic system |

The constant power variable displacement pump is used for controlling the movements of crane. Oil tank capacity: Approx. 900L. |

Counterweight |

Total weight is 9t. 3 counterweight combinations of Ot, 5.5t and9t are available.

|

||

|

Operating mode |

Electric controlled pilot operation system is equipped with two electric proportional control levers controlling the main movements of the crane. |

Electrical system |

DC 24 V, two batteries inseries. |

||

|

Gearbox |

6WG210, automatic transmission imported from ZF Germany, with 6 forward and 3 reve rse gears available. |

||||

|

Axles |

Exclusive axles imported from KESSLER Germany, with both front axle and rear axle for driving and steering. |

Additional equipment |

|||

|

Suspensions |

Front axle is connected with frame rigidly, swing rigidly lockable hydraulic suspension is used for rear axle. Road shock is buffered and travel smoothness is improved when driving on roads. The rear suspension cylinder may be locked to rigid state so as to meet the requirement for travel with a load suspended. |

Auxiliary which system |

Driven by a hydraulic motor, with build-in planetary gear reducer, constant closed brake and rotation resistant wire rope equipped.

|

||

|

Tires |

4 tires, each axle is equipped with single tire, large bearing capacity.. Tire specifications:29.5 R 25. |

Jib |

2-section, lattice and box welding structure, with0° ,20° and 40° jib offset angles avai lable. Jib length:9.5m~ 17.5m. |

||

|

Steering |

Electro-proportional hydraulic multi-mode steering: front axle independent steering, tight turning radius steering, crab walk steering and rear axle independent steering are available. |

Air conditioner |

Equipped in the cab, so as to improve the comfort fbr operator. |

||

|

Brakes |

Service brake: double-circuit hydraulic disc brake, acting on all wheels. Automatically braking function works when the pressure in braking system is too low. Parking brake: spring-loaded brake, acting on the front axle, hydraulic-released independent disc brake. |

Hook |

70t hook block; 5t hook block. |

||

|

Main winch system |

Driven by a hydraulic motor, with build-in planetary gear reducer, constant closed brake and rotation resistant wire rope equipped, having features of high speed with light load and low speed with heavy load. |

Differential locks |

With these differential locks fitted, pass ability may be improved in case of slipping when driving on difficult roads or single-side tires slipping due to partly suspended drive wheels. |

||

|

Slewing system |

Single-row four-point ball contact slewing ring, driven by a hydraulic motor, with built- in planetary gear reducer and constant closed brake equipped. 360° continuous rotation is available. |

|

|

||

|

Product parts list is as mentioned above, please refer to the product quotation for specific parts. |

|||||

|

XCMG——RT70E |

|||||