XCMG Official Manufacturer Forestry Clamp Loaders LW700KN for sale

Summary

- Overall Dimension(L*W*H): 9230×3017×3614 mm

- Weight:24500 kg

- Model Number: LW700KN

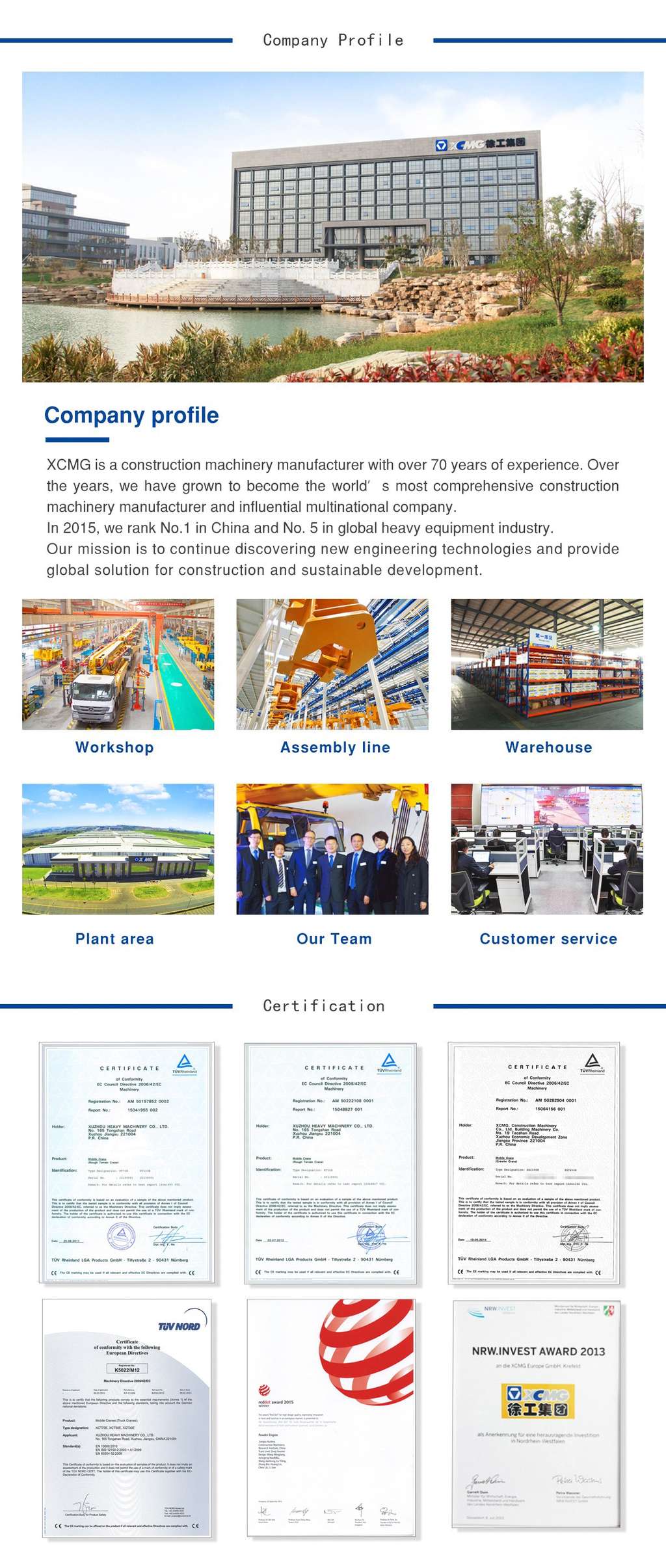

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:24500.000kg

- Condition:New

- Moving Type:Wheel

- Rated operating load:7000 kg

- Machine weight:24500 kg

- Dump clearance at maximum lift:3168 mm

- Reach at maximum lift:1283 mm

- Wheel base:3450 mm

- Tread:2360 mm

- Unloading Angle:45°

- Caliper Width:2685 mm

- Maximum Opening Size:2672 mm

- Minimum Rounding Diameter:Φ1000 mm

- Minimum Ground Clearance:520 mm

- Max. breakout force:200 kN

- Max. horse power:220 kN

- Hydraulic cycle time-raise:≤6.5 s

- Total hydraulic cycle time:≤11 s

- Min. turning radius over tyres:5950 mm

- Gradeability:28°

- Tyre size:26.5-25-20PR

- Engine Power:226 kW

- Hydraulic Working System Pressure:20 Mpa

- Hydraulic Steering System Pressure:19.5 Mpa

- Track Speed:Forward gear:0-6/11/22/34 km/h,Reverse gear:0-7/12.7/27 km/h

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

XCMG’s new design of forestry

clamp loader is equipped with wood clamp specially designed for log handling. A

transverse force bearing mechanism is specially designed to address the complex

movements such as flushing and pulling of materials by the upper clamp and the

damage to the upper clamp due to the turning or walking of the machine on bumpy

roads, and this design has applied and obtained a patent. The hinge point of

the clamp is optimized and the optimized Z-shaped reversal six-bar mechanism

increases the breakout force by more than 35% at high-level unloading

positions, which can better meet the reversal the gripping force of the clamp,

and the arm of force of the oil cylinder of the upper clamp is extended to

increase the clamping force by more than 30%; the upper clamp is widened and a

reinforcement plate is added to the side to increase structural strength while

a wear-resisting plate is added to the bottom of lower clamp to extend the

service life of the clamp; the zigzag structure can increase the clamping force

to prevent slipping and shifting of timber; the enlarged diameter of upper

steel pipe can improve the clamp strength; the extended tooth top of the lower

clamp can increase the lifting efficiency; the protective plate is widened and

the protection for cylinder joint and pipeline is strengthened; the machines

and tools are all made of high-strength materials and the key force-bearing

parts are structurally reinforced; double anti-wear design is adopted and the

worst working conditions are considered through CAE analysis to prevent open

welding and cracking. A protective net is added to the cab that can ensure easy

startup and clean, increase the exchange for external fresh air, increase

internal press, and prevent external dust; a protective bracket is added at the

bottom and thickened steel plates are used in the engine, gearbox, and front

frame to prevent branches and leaves from entering into the engine compartment

and chassis, enhancing the protection for critical components.

XCMG’s new design of forestry

clamp loader is equipped with wood clamp specially designed for log handling. A

transverse force bearing mechanism is specially designed to address the complex

movements such as flushing and pulling of materials by the upper clamp and the

damage to the upper clamp due to the turning or walking of the machine on bumpy

roads, and this design has applied and obtained a patent. The hinge point of

the clamp is optimized and the optimized Z-shaped reversal six-bar mechanism

increases the breakout force by more than 35% at high-level unloading

positions, which can better meet the reversal the gripping force of the clamp,

and the arm of force of the oil cylinder of the upper clamp is extended to

increase the clamping force by more than 30%; the upper clamp is widened and a

reinforcement plate is added to the side to increase structural strength while

a wear-resisting plate is added to the bottom of lower clamp to extend the

service life of the clamp; the zigzag structure can increase the clamping force

to prevent slipping and shifting of timber; the enlarged diameter of upper

steel pipe can improve the clamp strength; the extended tooth top of the lower

clamp can increase the lifting efficiency; the protective plate is widened and

the protection for cylinder joint and pipeline is strengthened; the machines

and tools are all made of high-strength materials and the key force-bearing

parts are structurally reinforced; double anti-wear design is adopted and the

worst working conditions are considered through CAE analysis to prevent open

welding and cracking. A protective net is added to the cab that can ensure easy

startup and clean, increase the exchange for external fresh air, increase

internal press, and prevent external dust; a protective bracket is added at the

bottom and thickened steel plates are used in the engine, gearbox, and front

frame to prevent branches and leaves from entering into the engine compartment

and chassis, enhancing the protection for critical components.