XCMG Official 20 tons Detachable container garbage truck XZJ5250ZXXD5

Summary

- Overall Dimension(L*W*H):8350×2500×3140 mm

- Weight:11680kg

- Model Number: XZJ5250ZXXD5

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:11680.000kg

- Condition:New

- Moving Type:Wheel

- Top model:LBH20B

- Chassis model:DFL1250A13

- Energy model:ISDe245 50

- Emission standard:GB17691-2005(Standard ChinaⅤ),GB3847-2005

- Total mess:25000kg

- Curb mess:11680kg

- Rated payload:13190,13125

- Wheelbase:4350+1350 mm

- Hook to rear roller distance:5300 mm

- The maximum inclination:≥49°

- Hooking time:≤60秒

- Discharging time:≤60秒

- Maximum pressure of hydraulic:28MPa

- Operation manner:Pneumatic,electric,manual

- Hook capacity:20000 kg

- Height of hook center:1570 mm

- Swing/slip:1100 mm

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

XZJ5250ZXXD5 Detachable ContainerGarbage Truck

XZJ5250ZXXD5 Detachable ContainerGarbage Truck

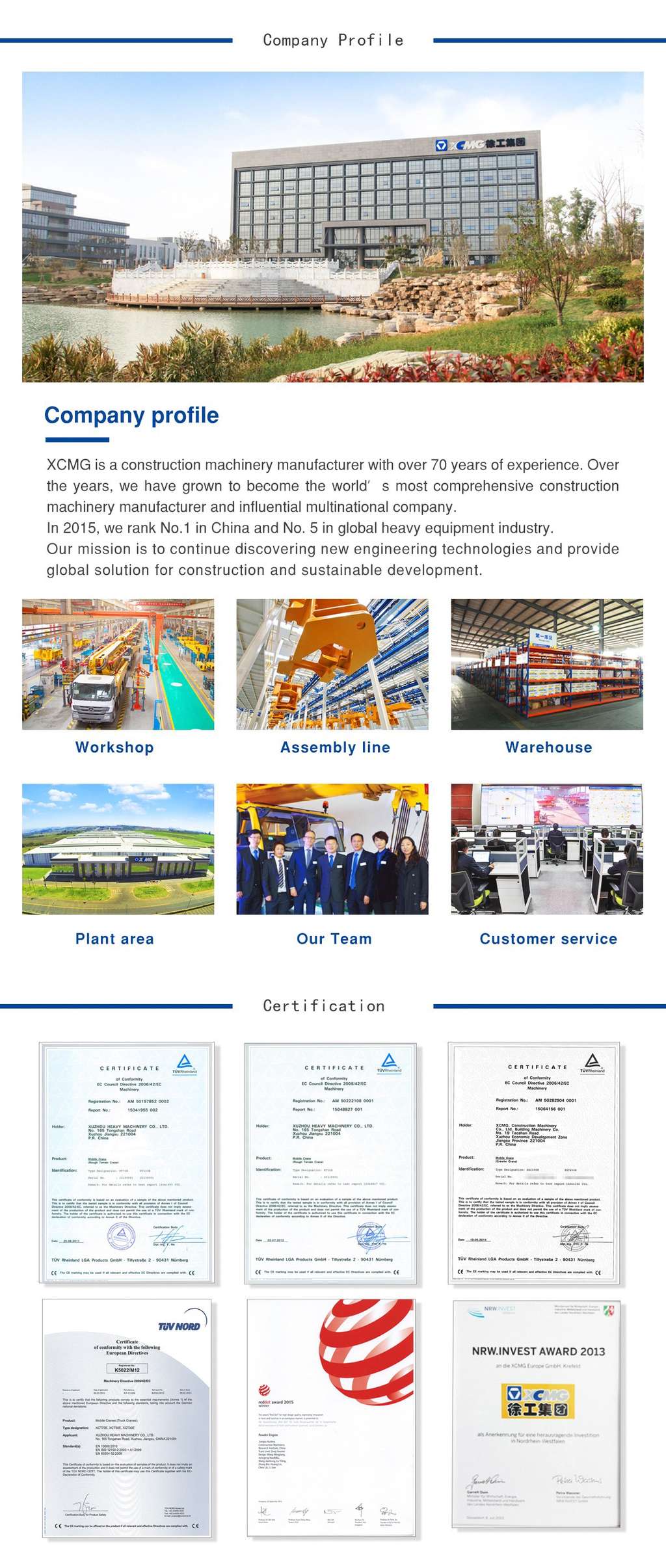

1. The Company is one ofnational industrial standard drafters, making sure the technologicaladvancement and the leading level. Besides, the Company is armed with anexperienced R&D group and has lots of loading & unloading devices andextensive experience in automobile repacking and design. The product isbeautiful, safe and reliable. The Company is the only enterprise with thequalification of loading and automobile repacking in China. Its quality is at atop-ranking level in China.

2. The structural styleincludes slide arm and swing arm. It is featured by flexible and stableoperation. At the same time, it also reduces the height of motion curve.

3. The mode of springself-reset is adopted for the (self-dumping) front lock. It is featured bysimple, stable and reliable operation and high integration of action functions,reducing the probability of mis operation.

4. (Self-dumping) rear lock isadopted for the hydraulic tank, with a simple and reliable structure and stronguniversality. A stroke valve is added to the hydraulic pipeline, in order tolimit the operation of sliding arm (swing arm), resulting in higher reliabilityof the product.

5. Internationally advanced 3Ddesign software Pro ENGINEER is used as the development tool of the product. Inthe parts design phase, we began to consider optimal design. We analyzed thestress of every part. The safety factor is higher than 1.5 for all structuralparts. Meanwhile, Q690 high-strength steel plate is used for all key structuralparts. Thus, the strength of our products can reach the design requirements. Onthis basis, the weight is also the lightest for our products, remarkablyincreasing the load capacity of the vehicle.

6. An idler wheel support isadded to the auxiliary frame. When the tank is sliding on the supportingsurface, the sliding rigid model of the tank and the supporting seat is changedinto rolling friction, reducing the wear at the tank bottom, and improving theservice life of the tank.

7. All oil cylinders arepurchased from well-known domestic brands. All sealing rings are imported.Well-known domestic plunger hydraulic pump is selected. The working pressure isas high as 30MPa. It is featured by stable and reliable working, reducing thedamage to the pump caused by pressure peak and guaranteeing the stability ofthe hydraulic system.

8. An electromagnetic balanceoverflow valve is added onto the main oil cylinder, so as to avoid acceleratedsliding under the dead load of the tank and the cantilever crane when the mainarm takes back and is about to be put horizontally and to realize safe andstable operation. Moreover, it also avoids the impact between the tank and theupper part of drag arm hook as well as the damage to the automotive framecaused by tension of the main oil cylinder.

9. Macromolecularoil-containing nylon is adopted for the sliding block on the sliding arm, whosefriction coefficient is lower than 50% of ordinary nylon. However, its abrasiveresistance is 10 times of ordinary nylon, remarkably reducing the number ofmaintenance times caused by nylon wear.

10. All operations can befinished in the driving cab. It is simple and convenient. Besides, severaldetecting points are increased, resulting in interlocking of various actionsand making sure the action safety and reliability.

11. Rear support underdiversified structural styles can be allocated. It can be matched with moredifferent chassis. Various structural styles are provided with a detectorswitch, so as to make sure effect working of the rear support and properlyprotect the cross beam at the chassis tail.

|

The vehicle model |

XZJ5250ZXXD5 |

|

Top model |

LBH20B |

|

Chassis model |

DFL1250A13 |

|

Energy model |

ISDe245 50 |

|

Emission standard |

GB17691-2005(NationalⅤ),GB3847-2005 |

|

Total mess |

25000kg |

|

Curb mess |

11680kg |

|

Overall dimension |

8350×2500×3140 |

|

Rated payload |

13190,13125 |

|

Wheelbase |

4350+1350mm |

|

Front/rear |

1480/1170mm |

|

Hook to rear roller distance |

5300 mm |

|

The maximum inclination |

≥49° |

|

Hooking time |

≤60 s |

|

Discharging time |

≤60 s |

|

Maximum pressure of hydraulic system |

28MPa |

|

Operation manner |

Pneumatic, electric, manual. |

|

Hook capacity |

20000 kg |

|

Height of hook center |

1570 mm |

|

Swing/slip. |

1100mm |