.jpg_l.jpg)

WEIHUA 320t Overhead Crane for Foundry

.jpg)

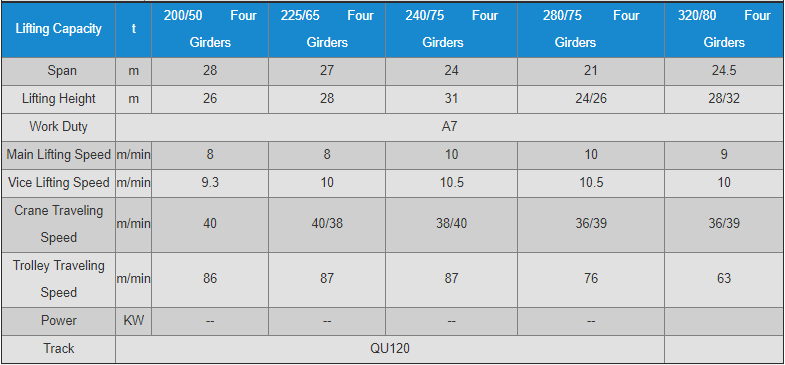

Specs & Compare

Details

Specifications

- Weight:2500.000kg

- Warranty Period:3 Months

- Condition:New

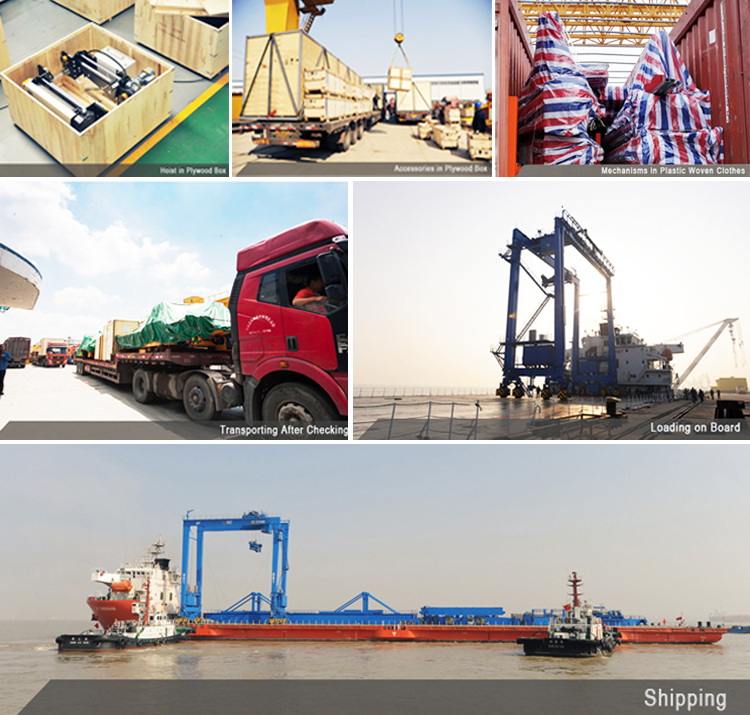

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

Product Name: 320t Overhead Crane for Foundry

Product Name: 320t Overhead Crane for Foundry

Structure: 4 girders and 6 rails

Lifting Capacity: 320t

Application: Metallurgical plant

This 320t overhead crane for foundry is the biggest metallurgical foundry crane ever made in Henan Province, China. During manufacture and installation, we have obtained valuable experiences to lay the foundation for manufacturing crane with more technology and complex structure.

The main structure of this 320t foundry crane is designed with 4 girders and 6 rails. The highlights of this crane are integral processing technology and secondary assembly technology. For the first time assembly, the welding components sizes are fixed and adopt flat position welding to ensure the quality of welding seams; and the secondary assembly is to release welding stress before the integral processing of the bridge to ensure the stability and accuracy of product process precision. The two-times assembly technologies could maximally ensure the precision of gauge, diagonal and span, as well as users' site installation..jpg)

Features of Weihua Foundry Ladle Crane:

1. It adopts Siemens PLC and Siemens inverter for control and drive. At the same time, Profinet is used for communication between PLC and inverter. It is equipped with communication detection function, which can detect the working status of each station in real time.

2. A monitoring system is installed to monitor the working status of the crane in real time.

3. The hoisting mechanism of the ladle crane adopts redundant system design to ensure the safety and reliability of lifting liquid metal.

4. It is with wireless transmission and electronic scales, real-time transmission of the weight of liquid metal.

5. Each crane is designed with an electric room, and an electric fan is installed in the electric room to ensure the safe and reliable operation of the electrical equipment.

6. The 250t ladle crane hoisting mechanism adopts the planetary reducer structure. If one motor fails, it can still complete the lifting work in a short time.

7. Mother-child trolley to realize the unmanned automatic hanging ladle and save the cost.

8. The overall design is with lightweight and compact structure.

9. Low height, light self-weight, small hook limit, large working range.

10. High quality parts, durable, safe and reliable.

11. Less maintenance and repair costs.

12. Small total crane power and low energy consumption.

13. Frequency control, smooth lifting and less impact.

.jpg)

Certified for 3 years

Rating

Response Time

08:00-24:00

Year of establishment

1988

Add a Product

1 selected

Confirm

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)

.jpg_t.jpg)