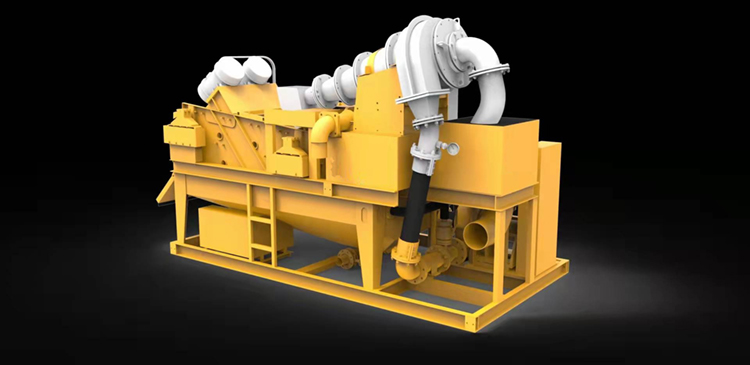

Pluto RMT250 mud sand removal and purification equipment machine price

Specifications

- Weight:1.000kg

- Condition:New

- Moving Type:Other

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Delivery Port:Any Port In China

Pluto RMT250 mud sand removal and purification equipment machine.

1.Technical features:

The whole machine is operated by electromechanical control buttons, which is very simple to use.

The structure is compact and convenient for the transfer use and installation of the equipment.

Low energy consumption and large processing capacity per unit time.

It can effectively control the cost of construction slurry and slurry making.

The solid-liquid separation performance is stable, and the sand content of the purified mud can meet the sand setting control standard at the bottom of the grouting pile hole.The average particle size D50 of the particles contained in the purified mud is less than 0.060mm.

It has two flow control functions, which can realize the internal fluid circulation after the external slurry supply is cut off, protect important components from damage, and adjust the separation accuracy of thick slurry.

2. typical applications:

Rmt200 (250) mud treatment equipment is a pile foundation auxiliary equipment supporting the construction machinery of grooved foundation, bored foundation and trenchless pile foundation.

It can effectively control the sand content in the construction mud and the particle accuracy in the slurry, carry out solid-liquid separation of solid particles in the slurry, and dehydrate and discharge the separated waste residue. The equipment is helpful to improve the pore forming rate of pile foundation, reduce the cost of slurry during construction, and realize the recycling of construction slurry.

This type of equipment is widely used in underground diaphragm wall construction and deep hole drilling construction, especially in coastal areas or economically developed areas with large sand content, high construction environmental protection requirements and expensive mud treatment costs.

|

Max Capacity(m³/h) |

250m3/h |

Total power(KW) |

58kW |

|

Cut point(mm) |

d50=0.060mm |

Main pump flow |

250m3/h |

|

capacity ballast |

25-80t/h |

Main pump motor power |

55kW |

|

Maximum moisture |

< 30% |

Vibrating motor power |

1.5kW |

|

Maximum purification effect (sludge specific gravity) |

< 1.25g/cm3 |

Transportation dimension (L×B×H) |

4.00m×2.40m×2.90m |

|

Marsh Funnel Viscosity |

≤40s |

Largest dimension (L×B×H) |

4.47m×2.29m×2.7m |

|

Soxhlet funnel viscosity |

≤30s |

Total weight(kg) |

5400kg |

|

maximum specific gravity of sewage slurry that can be treated is less than |

1.5g/cm³±0.1 |

|

|