Mengke automatic oil separator M3S

Specifications

- Weight:100.000kg

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

Product features

fully automatic Totally closed No clear out integrated The effect is good No peculiar smell

Hazards of Restaurant Sewage ,

■Blocking municipal pipe network

■Corrosion of drainage pipes

■ polluted water

■Influence on traditional water treatment effect

■ odor generation

■ made into "gutter oil"

working principle

The advanced oil-water separation technology of Munch, Germany, and the world's advanced nine step separation process are used for advanced treatment of restaurant wastewater. The qualified rate of the product is 100%.

■Eliminate "gutter oil" ■ prevent pipe network blockage ■ treat drainage up to standard ■ improve living environment ■ improve living standard

Nine stage separation technology

Primary filtration: kitchen sewage enters the primary treatment module for solid-liquid separation, and solid particles with diameter > 5mm can be filtered out.

Secondary slag removal: screw type automatic slag removal device with chopping function is set in the primary treatment module to lift the solid particles with diameter > 5mm intercepted by the primary filter out of the primary filter bin and transport them to the slag collecting bucket.

Three stage pre sedimentation: after the first stage filtration, the small particles and sludge enter the bottom of the primary treatment module for sedimentation, the liquid after sedimentation enters the advanced treatment module, and the solid impurities deposit in the small sedimentation bin at the bottom of the primary treatment module, which is regularly discharged to the slag collection bucket by the staff.

Four stage separation: the oil-water mixture separated by the primary treatment module enters into the large sedimentation bin of the advanced treatment module, and eddy current sedimentation is formed under the action of the fully automatic oil and slag guiding system. The specific gravity of oil and water is different, the oil floats gradually, and the small particles and sludge precipitate at the bottom.

Five level deep sedimentation: after sufficient time of sedimentation, the small particles and sludge gradually settle at the bottom of the sedimentation bin, and finally enter into the slag collecting well at the bottom of the sedimentation bin. The slag collecting well is equipped with a slag guiding device. Open the valve and the slag guiding device to guide the small particles and sludge to the slag collecting bucket.

Six stage oil separation: the oil with small specific gravity is thoroughly introduced into the oil drain through the automatic oil guide system. The latest generation of heat conduction constant temperature technology is used to heat the oil 360 degrees, keep the oil liquid all the time, open the oil drain valve and discharge it to the oil barrel.

Seven levels of advanced treatment: the new generation of scum treatment process can be used to remove the scum on the surface of the water.

Eight level automatic backwashing: use the treated water to realize the internal circulation of the equipment, and comprehensively clean the filtration system and slag removal system. Prevent clogging.

Grade 9 sewage discharge: the sewage continuously enters the water storage chamber through the siphon device, which meets the discharge standard, and is lifted and discharged into the municipal pipe network by the sewage pump.

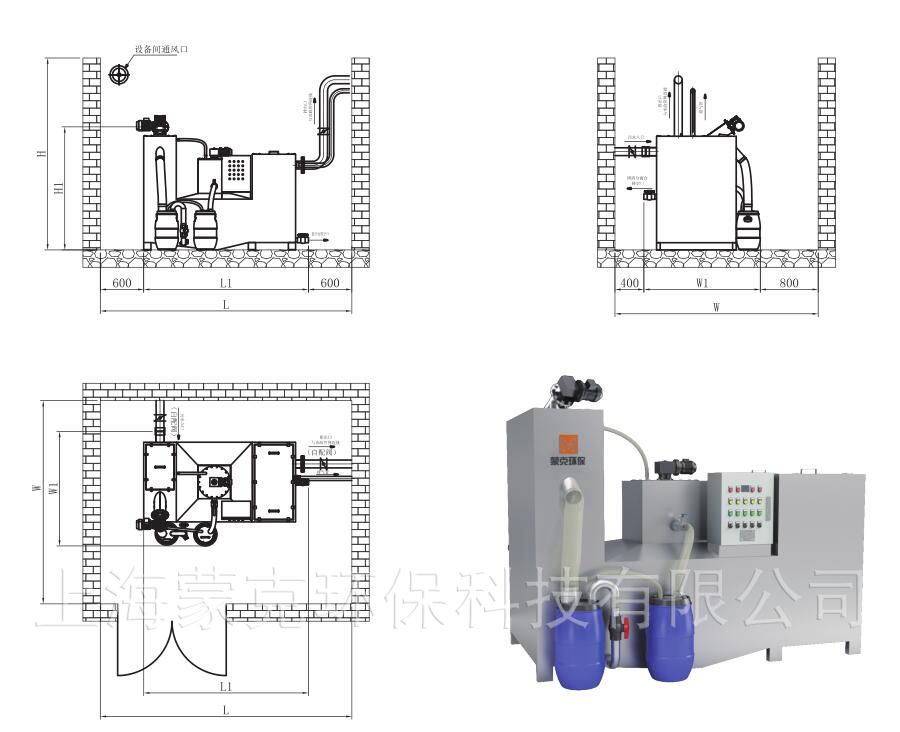

Product dimension drawing

Product display