XCMG Official Manufacturer TJ180 Bridge-erecting machine for sale

Summary

- Overall Dimension(L*W*H): 58200×4200×8400 mm

- Weight:150000 kg

- Model Number: TJ180

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:150000.000kg

- Condition:New

- Moving Type:Other

- Rate lifting capacity:180 t

- Total weight of main machine:150 t

- Suitable span:≤32 m

- Erection beam piece:≤30‰

- Erection bridge type:Straight axle,curved axle R≥400m

- Bridging speed:1.5 pcs/h

- Via hole speed for complete vehicle:5 m/min

- Lengthways move for crown block:5 m/min

- Hanging beam lifting speed:0.7 m/min

- Lateral moving speed of hanging beam complete machine:1.6 m/min

- Outline dimension of complete vehicle:58.2*4.2*8.4 m

- Power equipment:100 kW

- Rate/Maximum working pressure for hydraulic system:25/31.5 Mpa

- Maximum outline dimension of erection beam piece:32*2.6*3.3 m

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

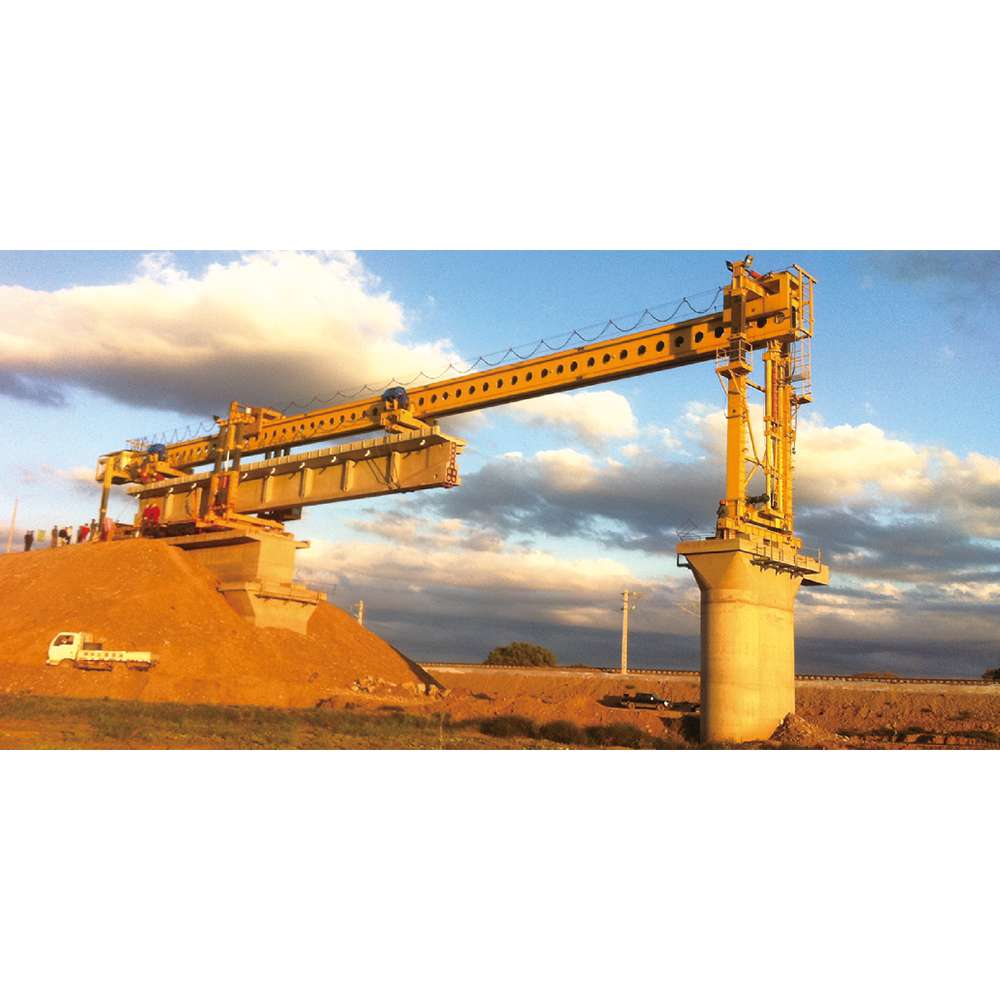

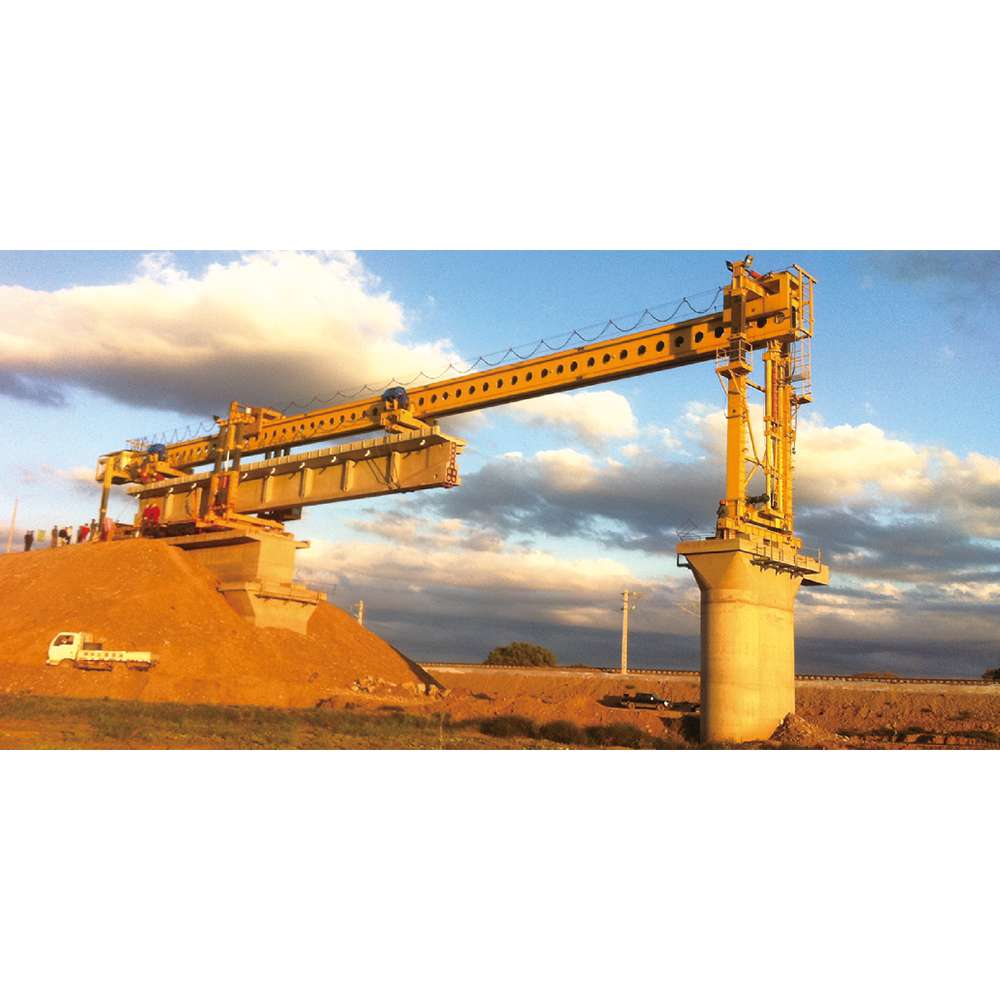

TJ180 Bridge-Erecting Machine

TJ180 Bridge-Erecting Machine

Main Applications

Thisproduct is used to erect the ≤32m concrete girders (girders 2101, 2202, and2103 for common bridges), girders 9753 and 2051 for special bridges, and 25mrail section pavement for type III sleepers for ≤200km/h mixed passenger andfreight new and renovated railways.

Thismachine is of single-boom simple support type and can mechanically traverse thegirder segments in full amplitude to realize one-time proper placement ofgirder segments, featuring simple structure, light weight, high safety andreliability, high automation level, and easy transportation.

Technical Features

Thesingle-boom simple support type can mechanically traverse the girder segmentsin full amplitude to realize one-time proper placement of girder segments,featuring high working efficiency, high working safety and reliability, andeasy transportation.

Theoperating system adopts the PLC programmable logic controller to effectivelyrealize self-locking and interlocking and eliminate the potential unsafe issuesdue to maloperations. The variable frequency speed regulation control isapplied for the through-hole and traversing of machine and the traveling ofoverhead traveling crane to ensure steady start and braking and reliablerunning.

Thedouble rack drive technology is applied for the traveling of overhead travelingcrane to ensure more uniform force application, more stable running, and moreaccurate positioning of the traveling.

Withextensive adaptability, it can meet the erection needs of large gradient, smallcurve, and tunnel portal bridges.

| Rate lifting capacity | 180 t |

| Total weight of main machine | 150 t |

| Suitable span | ≤32 m |

| Erection beam piece | ≤30‰ |

| Erection bridge type | Straight axle, curved axle R≥400m |

| Bridging speed | 1.5 pcs/h |

| Via hole speed for complete vehicle | 5 m/min |

| Lengthways move for crown block | 5 m/min |

| Hanging beam lifting speed | 0.7 m/min |

| Lateral moving speed of hanging beam complete machine | 1.6 m/min |

| Outline dimension of complete vehicle | 58.2*4.2*8.4 m |

| Power equipment | 100 kW |

| Rate/Maximum working pressure for hydraulic system | 25/31.5 Mpa |

| Maximum outline dimension of erection beam piece | 32*2.6*3.3 m |