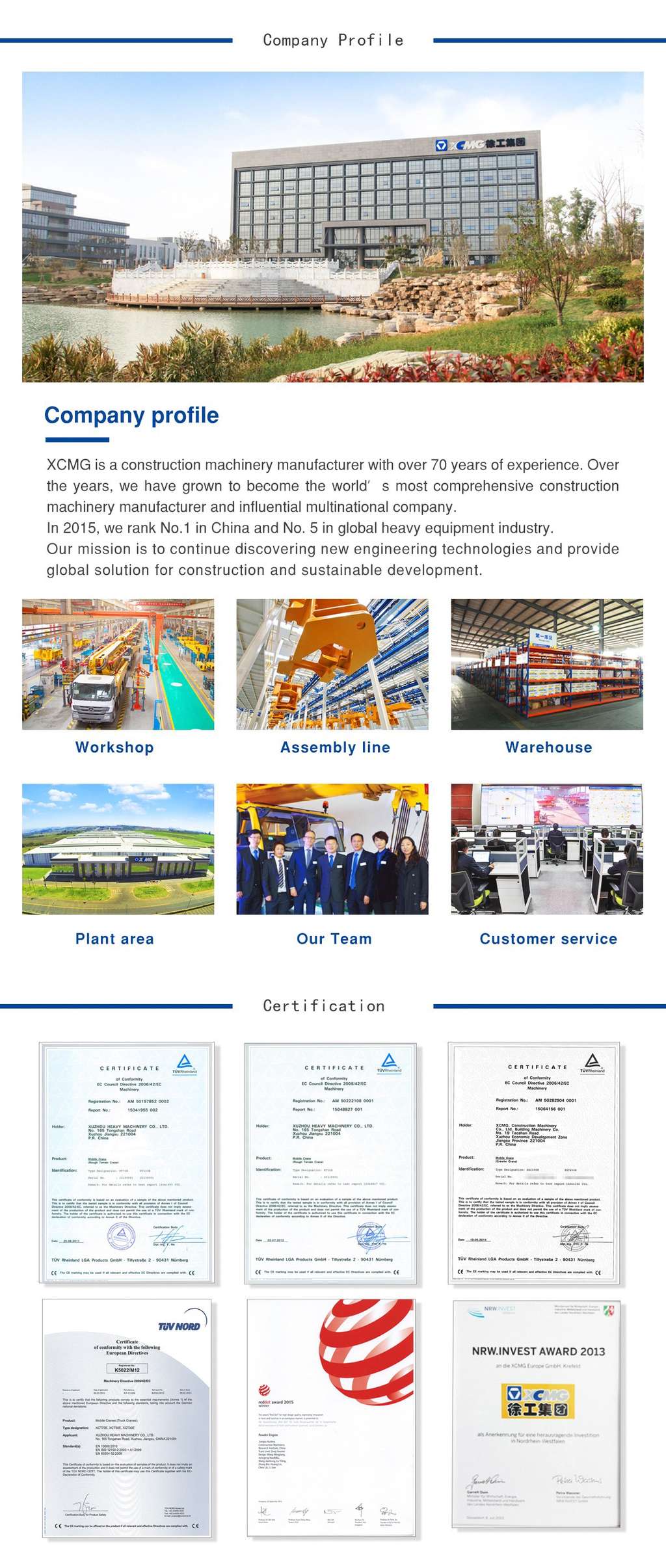

XCMG Official Manufacturer 8 tons Compressed Garbage truck XZJ5160ZYSD5 for sale

Summary

- Overall Dimension(L*W*H): 8500×2500×2965mm

- Weight:15800 kg

- Model Number: XZJ5160ZYSD5

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- Weight:15800.000kg

- Condition:New

- Moving Type:Wheel

- Chassis Model:DFL1160BX1V

- Total Weight:15800Kg

- Curb Weight:9350kg

- Rated Payload:6255kg

- The Volume Of Carriage:12.5m3

- Height from the ground:1040mm

- Fill Capacity:1.75m3

- Drain tank volume:350L+228L(main+vice)

- loading cycle time:—

- The loading Angle of the loader:—

- Hydraulic system rated pressure:19.6MPa

- Carriage Dimension(L*W*H):—

Packaging & Shipping

- Delivery Lead Time:7 days for ready goods

- Minimum Order:1 Piece

- Supply Ability:10,000 Set/ Sets per Month

- Total Quantity In Stock:Over 5000

- Delivery Port:Any Port In China

XZJ5160ZYSD5 Compressed Garbage Truck

XZJ5160ZYSD5 Compressed Garbage Truck

1、Good Sealing of the Vehicle. Xugong Brand XZJ5160ZYSD5 compression garbage truck box structure adopts a fully sealed design. The sewage tank at the back of the mounted part is used to store the sewage generated after the compression. Through the application of key technology and high-quality sealing materials, the phenomena of running, dripping, and leaking have been thoroughly solved, which thoroughly avoids secondary pollution in the process of the garbage compression,loading and transferring. Mainly reflecting in the following aspects:

①Sealed body with front and rear door design technology prevents sewage and odor leakage.

②Water baffle design technology effectively prevents splashing of the foul solution in the process of compression.

③The sink design technology effectively prevents the foul solution from leaking to the ground after aging of the sealing strip.

④Centralized sewage diversion design technology diverts all the foul solution to the drain tank

⑤The automatic anti-lock hook and the triple special CR neoprene seal strip U-to-top design technology make the connection between the compartment and the loader more stable and strengthen the sealing performance of the box

2、Compared with the track placed on the base plate of the trunk, the slide way structure of the push plate is bilateral trough type track, which has the advantages of high rigidity of the track, good stability, no deformation of the base plate, stable movement of the push plate, clean unloading of rubbish, reliable operation, etc.. Sliders of push plate are made of high-strength wear-resistant steel plate.

3、Adopting roller and nylon oriented mechanism, the slider

oriented device is of good performance, wear-resistance, high-strength and

self-lubrication. The movement of the nylon plate in the slide way depends on

the four sets of imported high density polyethylene-oriented support sliders,

which reduces the sliding resistance and the kinematic pair wear compared with

the rigid sliders commonly used in China, such as bearing steel. In particular,

compared with the domestic plastic slider used by peers, high-density

polyethylene slider is wear-resistant; there is no need to take replacement under

normal maintenance.

4、Adopting PLC (programmable logic controller) integrated control, the control circuit is generated in the PLC, and uses a logic circuit to ensure that all the operating instructions are executed in sequence. The external circuit connection reduces the failure rate, avoids accidents caused by mis operation and increases reliability; safety control facilities are required to install. The operation can be stopped under any circumstance and in any place, ensuring the safety of operators and equipment.

5、Compared with the high-pressure system with the constant

pressure of the whole system which is widely used in China, the optimized

hydraulic system with the medium and variable pressure has the advantages of

fast dynamic response, small internal heat loss, high work efficiency, short operation

cycle time and being easy to operate, especially reliable work, low failure

rate;

6、High Safety. With multiple safety protection devices, the vehicle is

equipped with16 safety protection devices and multiple safety warning signs, and

the control components are all high-quality products from abroad, and

structural and other components adopt high-quality products.

|

Item |

Index |

|

Product model |

XZJ5160ZYSD5 |

|

Chassis model |

DFL1160BX1V |

|

Engine model |

ISD180 50(132kw) |

|

Rated power |

132kw |

|

Curb mass |

9350kg (no feeding device, tipping bucket,

bucket shape) |

|

Total mass |

15800Kg |

|

Rated mass |

6255 kg (no feeding device, tipping bucket,

bucket shape) |

|

Overall dimension |

8500 mm(no feeding device, tipping bucket, bucket shape)×2500mm×2965 mm |

|

wheel base |

4500 mm |

|

Rave rail (hopper) volume |

1.75m3 |

|

Rave rail (hopper) dimension (width) |

1680 mm |

|

Clearance of rave rail (hopper) (unloaded) |

1040mm |

|

Compress mode |

Bi-directional compression |

|

Effective volume of garbage tank |

12.5m3 |

|

Drain tank volume |

350L+228L(main +vice) |

|

Hydraulic system rated pressure |

19.6MPa |

|

Operating mode |

Automatic operation/ operation by hand or by electricity/manual operation/remote operation |