Will Electric and Driverless Versions of Construction Machines Soon be Available?

Currently, electric and driverless construction machines are still

niche products or only at the prototype stage. However, market requirements and

manufacturers’ commitment are driving development.

The international construction machinery industry is under increasing

pressure to prevent both exhaust emissions and noise emissions. Construction

work elsewhere, for example in our inner cities, in hospital areas and in

enclosed spaces, will also have to be as quiet and involve as few air

pollutants as possible. The increased use of electric drives could be one way

of achieving this.

Electric versions of smaller construction machines in particular

already exist

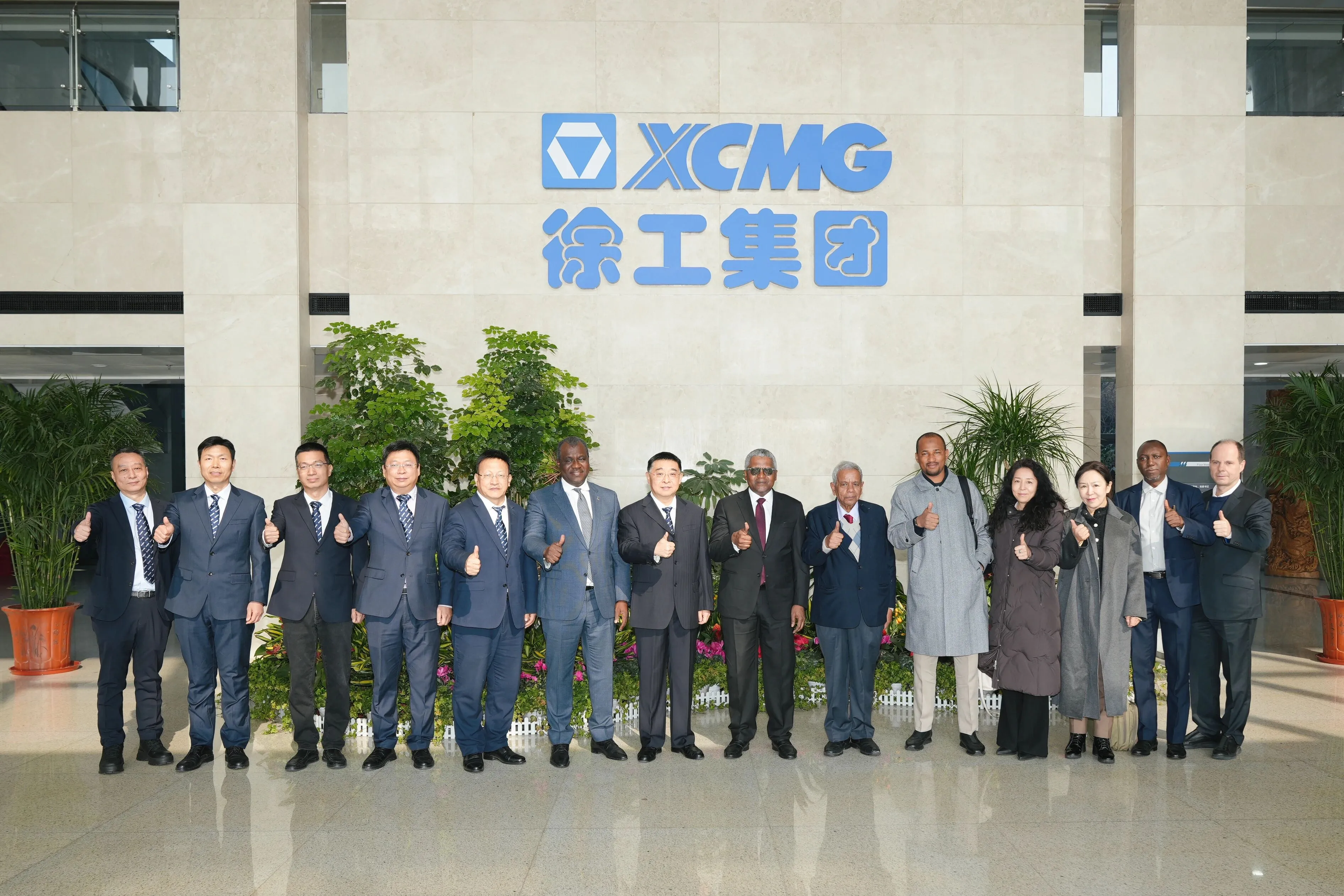

“Mechanical engineering companies have already launched e-solutions

for smaller machines, such as vibratory plate compactors, small rollers and

compact wheel loaders”, says Dr. Darius Soßdorf, Technical Regulations and Standardization

Consultant at the Construction - Equipment and Plant Engineering trade

association. Top manufacturers such as XCMG, Volvo and CAT have been very

active on the electrification scene for a few years now. Machinery factories

set the goal to build up a full electric product portfolio, which already

includes all essential e-devices and e-machines for developing inner-city

construction sites, from battery-powered rammers through to wheel loaders.

Hybrid solutions for higher power ranges?

In contrast, manufacturers are currently still struggling with electric

solutions for high-power-range machinery as the power required for the type of

work in question is too high. “In order to supply a ‘normal excavator’ weighing

approx. 15 tons with sufficient energy for a day shift, using current

technology the necessary battery pack would weigh tons”. In light of this,

hybrid vehicles are seen as another future area for development. “The device

would be electrically powered for light work, for example driving, and then a

combustion engine would be engaged where maximum power is required.”

An opportunity for recuperation and storage systems

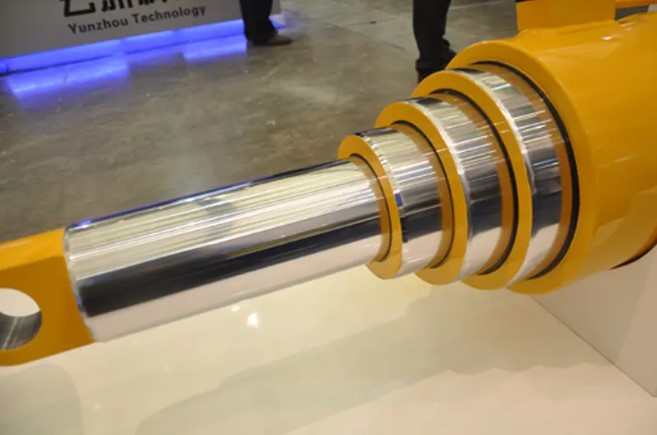

It is clear that when electric drive units are used, the machine’s

available energy must be used extremely carefully. “As such, solutions focusing

on energy recovery and storage will be increasingly in demand for electric and

hybrid machines in particular,” says Prof. Dr. Eng. Frank Will with certainty. The

current Endowed Chair of Construction Machines at the Technical University of

Dresden continues: “Whenever a machine works largely intermittently, these

systems can offer considerable potential to make savings.”

Driverless construction machines are already in use in the mining

sector

Like electrification, driverless vehicles are also one of the hot

topics for future mobility. In relation to the rest of the construction

industry, a lot of headway has been made in the mining sector. For example, XCMG

and Caterpillar already sell commercially autonomous and semi-autonomous

operating systems for dump trucks, bucket-wheel excavators, bulldozers and low

loaders in the mining sector. Upgrading the hardware and software of other

manufacturers’ trucks has also been part of this line of business since last

year.