Torsa Launches Next Generation Collision Avoidance System

by Daniel Gleeson

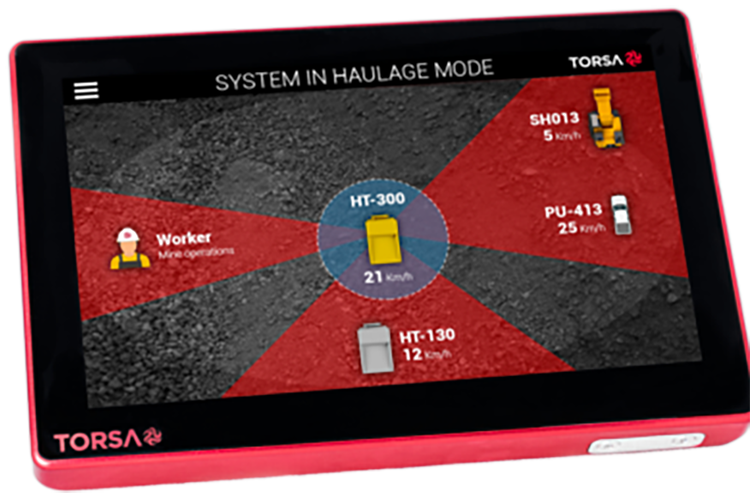

Torsa has unveiled its next generation

Collision Avoidance System for shovels, haul trucks, auxiliary and light

vehicles, building on the first version of its system that was deployed at

Antamina in Peru.

The Spain-based company says its latest CAS optimizes loading

operation, allowing the two trucks to be loaded simultaneously.

Gabino de Diego, the new director of Business Development for Torsa, explained: “For our first generation, our design team evaluated all the detection technologies available in the market. With the focus on reliability and operators’ safety, LiDAR became the technology of choice. Actually, Torsa were the first one in the market with a LiDAR-based CAS.

“Now, in our fourth generation, a new 3D LiDAR is able to scan

more than 900,000 points per second, for an extremely accurate map of the

vehicle’s surroundings. In addition to LiDAR, Torsa CAS system is equipped with

cutting-edge detection technologies to provide maximum accuracy: ToF, UWB and

high precision GPS.

“The combination of all those technologies allows our system to

detect vehicles and other equipment with centimetric precision.”

Torsa has developed a user interface as part of this latest

update, taking on feedback from users to streamline the information required

for both the people running the vehicles and equipment and for the ones in the

control rooms, “reducing the information noise and providing a minimal invasive

system”.

“For example, in our fourth generation CAS system, we have

incorporated a predictive algorithm to avoid false positives because we know

that this is key for someone who is driving many ours every single day,” de

Diego said.

He added that the company’s CAS system has clocked up millions

of hours of operation to date in various mines, with plans to bring the

technology to mines in US, Canada, Africa and Australia from this year onwards.

Like all TORSA solutions, the collision avoidance system for

shovels, trucks and light vehicles is integrated into the TORSA Cloud

environment, ensuring the correct interaction, operation and technical

information management for all clients, the company says. The cloud-based

platform provides real-time data and information that can be used to target

specific issues in the mine, running campaigns to optimize the operation.

“Thanks to the business intelligence modules included in the

platform users are able, for example, to play back incidents and vehicle

interactions for detailed analysis, or rank the operators based on multiple

parameters to study and optimize behavioral KPIs,” de Diego said.

TORSA collaborates actively with the International Council on

Mining & Metals (ICMM) where the company is involved in the Innovation for

Cleaner Safer Vehicles (ICSV) program, which brings together 27 of the world’s

leading mining companies and technologies suppliers to collaborate in a

non-competitive space in order to accelerate the development of a new

generation of mining vehicles.