Pump Car Maintenance Tips You Need to Know!

The high outdoor temperature in summer is a great test for pump trucks

and pump workers. Here’s the summer maintenance guide for pump trucks.

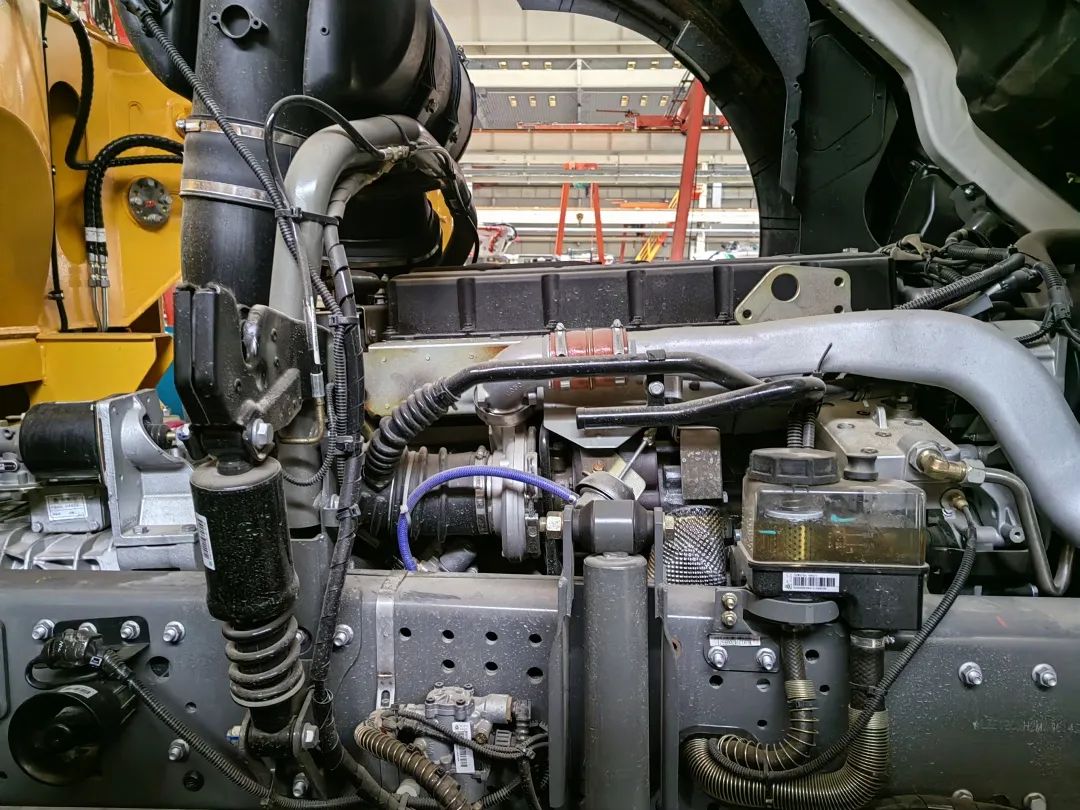

Engine

The long-term high-temperature working condition easily damages the

engine cylinder gasket seal. In order to better control the engine temperature

of the pump truck, you need to pay attention to the following points:

1. Antifreeze must be used for the engine. The antifreeze must be

within the validity period and the amount of antifreeze must be sufficient;

2. Use regular diesel to prevent the engine temperature from being too

high due to inferior diesel;

3. Check whether the engine belt is worn abnormally, clean the engine

housing, remove oil and dust, and ensure that the engine heat dissipation is

normal.

Piston Coolant

There should be sufficient piston coolant in the washing room of the

pumping unit. During summer construction, the following two points must be

achieved for piston coolant:

1. Piston coolant must be changed frequently. When the piston coolant temperature

exceeds 40 ℃, it should be completely replaced even if it is clean to ensure

that it can cool and contract well;

2. In high temperature environment, the piston coolant should be the

water added with lubricant, which not only ensures the cooling effect, but also

will not cause waste and pollution due to frequent replacement of coolant.

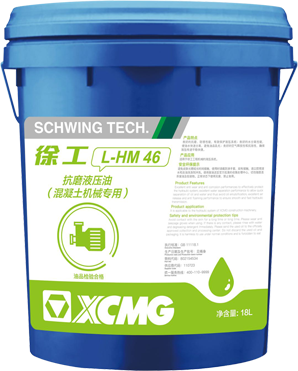

Hydraulic Oil

The high temperature in summer will reduce the viscosity of hydraulic

oil, resulting in poor lubrication effect. At the same time, the components of the

hydraulic system are prone to wear under high temperature, so the working

temperature of the hydraulic oil should be strictly controlled:

1. In the air temperature of about 35 ℃, 46# anti-wear hydraulic oil

shall be selected;

2. Replace the hydraulic oil regularly to ensure the quality and

cleanness;

3. check whether the working condition of the hydraulic oil radiator is

normal. If necessary, spray clean water on the radiator slowly (high-pressure

water gun is strictly prohibited) to assist in cooling.

Lubricating Grease

The viscosity of lithium grease will also decrease under high

temperature environment, so the following two aspects should be paid special

attention:

1. When the temperature exceeds 30 ℃, the 0# lithium base

grease must be used. The unused lithium grease can be well preserved and

reserved for use in autumn and winter;

2. Check whether the lubricating grease distributor has good sealing

effect to prevent the loss of lubricating grease.

Personnel Protection

Pump workers and other front-line workers should take heatstroke

prevention measures:

1. Take protective measures when going out, wear sun visors and cool

clothes;

2. Eat more vegetables and fruits, drink an appropriate amount of salt

water;

3. Always take heatstroke prevention drugs with you. In case of

heatstroke and other emergencies, go to a cool place in time.