How to Purchase a Quality Used Crane for Sale — 4 Big Considerations

With so many uses for cranes across both construction and industrial

applications, it isn’t surprising that used cranes are a popular option for

anyone looking for a cost-effective way to add these machines to their fleet.

But, before you buy a used crane, there are several factors you need to

consider before making an informed decision.

Aside from finding a crane that is structurally and mechanically sound,

you will also need to think about how much the crane will cost you each year to

operate. You’ll need to consider expenses incurred from regular maintenance,

component repair, or parts replacement.

Used cranes that are part of a large rental fleet will be more likely

to have kept the cranes in top shape through the lifetime of the crane. A

full-service crane rental operation must follow certain requirements and

guidelines related to crane maintenance. In general, OSHA requires inspections

of operational cranes once every month while the equipment is in operation.

However, cranes that see consistent use in the field will require more

frequent inspections to ensure safe operation. To avoid a sudden breakdown of

the equipment or costly repair, it’s a good idea to only buy a crane that has

verifiable inspection history, including an accurate record of any part

replacements.

In short, knowing what to look for in a quality used crane can save you

time and money in the long run. Read on to learn more ways to identify a

reliable crane so you can feel more confident about your purchase.

1. Budget

Having a plan on how much you plan to spend will help you narrow down

your search. The amount of money you can expect to spend is relative to your

requirements and the type of crane you consider purchasing. You want to find a

crane that can handle the lifting capacity you need, the height requirement of

your lifts, along with a crane that can manage your typical project’s terrain,

as most of a crane’s cost lies in the type and size of crane to ensure it can

handle your requirements. You’ll also need to consider the age and condition of

the crane when it comes to budget as well. Like with cars and other

automobiles, a combination of age, mileage (or hours in the case of some

cranes) play a role in determining the price.

2. Lifting Capacity and Crane Model Needed

If you are looking for a used crane, a key consideration is to make

sure you understand the maximum lifting capacity requirements you’ll have for

the work you want the crane to perform. You will need to calculate the biggest

lift requirements, the maximum radius required, and what terrain the crane will

most frequently be used on to determine what crane will work best.

So, for example, if the largest lifting capacity you will have been 10

tons at a 100 ft radius, you will need a crane that can lift that amount so

that anything below that maximum lift and maximum radius level is covered.

Similarly, if you’re most often going to be performing lifts in more complex

terrain, you may consider a rough terrain crane or a crawler crane versus an

over-the-road machine like a hydraulic truck crane.

Aside from the crane’s lifting capacity, some other questions to ask

yourself are:

What will the crane be used for?

There are a wide variety of cranes available on the market today, and

each model has unique attributes for performing specific tasks. For example, a

hydraulic truck crane is best used for smaller lift projects in tighter spaces.

If you need to carry loads across uneven or muddy surfaces, a rough terrain

crane or crawler crane would be ideal. Large-scale projects like constructing a

high-rise apartment building will usually require a telescopic crawler crane or

tower crane. Anticipating the most common tasks for your used crane will help

to determine the type and model of the used crane you need.

How many hours will you use it and what is the utilization?

Before buying a used crane, you’ll want to consider its projected daily

use and the kind of work the crane will do. If you expect to use the crane

during much of the workday, you’ll want to find a model that can stand up to

the rigors of constantly bearing weight without needing extensive repairs or

part replacement.

On the other hand, you may not need a recent model used crane on the

market if you plan to only use it occasionally to move select materials around

the job site.

Like mileage with cars, cranes record hours operated as a measurement

of usage. This is an important figure to consider when determining how often

the used crane you purchase will be running after you buy it. Some higher hours

or miles (for mobile cranes) may mean you’ll have to anticipate more

maintenance and repair costs when buying a used crane.

How often are you going to have to move the crane?

Another factor to consider is the type of mobility you require from the

crane. Do you need a crane traveling over the road to the job site? Consider an

all-terrain crane or hydraulic truck crane. Other cranes like crawler cranes,

rough terrain cranes, and tower cranes require tractor trailers to deliver the

equipment to the job site and, in many cases, require assist cranes to put up

and tear down the crane. Consider if you’ll have access to the equipment

required to move cranes that don’t have the ability to drive over the road and

include the costs of moving and assembling the crane on a regular basis into

your financial assessment.

In what kind of environment will the crane be used?

Not all cranes are equally resilient against the elements or varying

terrain on a job site. Consider the type of environment your crane will

encounter and how this will impact operations. For especially soft or

waterlogged surfaces, you’ll likely need a crane that comes equipped with

components like all-terrain tires or tracks to keep the equipment stable and

grounded while in operation.

For dry or relatively smooth terrain, cranes mounted on conventional

tires may be more appropriate. You’ll also want to think about how the

outriggers will perform in the terrain the crane will operate on to ensure

stability when doing a lift.

3. The Crane’s History

It’s important to know the history behind the crane you’re looking to

purchase. You should not just look at its hours, age, make, and model, but also

the geographical location where the crane was used and the application it was

used for. Was the crane exposed consistently to harsh weather conditions? Did

the machine run constantly in its lifetime? Make sure you ask the right

questions, so you understand the background and usage of the crane you’re

considering buying.

The preventative maintenance history is also critical, as with any piece

of capital equipment. It’s a good idea to either inspect the crane personally

or hire a 3rd party to inspect it. At Maxim Crane, no matter the age of our

used equipment we follow the same rigorous service and maintenance program for

all our machines. In most cases, the used equipment we sell is either still

part of our active fleet or was recently retired from the fleet. When you buy used equipment from Maxim, you

can feel confident that you’re buying a well-maintained machine.

When shopping around, look for the following background information

when buying a used crane:

- A comprehensive history of the crane’s usage, including any substantial repairs or part replacements that have occurred over the years. Beware of buying a crane with any undocumented repairs or lapses in its service history.

- Make sure the equipment has received annual and quarterly inspections. Documentation of these inspections should be complete and up to date. Never buy a used crane that doesn’t come with all the necessary records regarding its inspection history.

- Buy equipment that is part of an active rental fleet and properly maintained. Typically, the equipment will be well-maintained because it is required to be 100% operational all the time. At Maxim Crane, our used equipment for sale is typically part of an active rental fleet and it is inspected and maintained on a consistent basis.

When evaluating the condition of a crane you intend to buy, it’s

important to look over the equipment with a fine-tooth comb. Any issues big or small

could indicate a more substantial problem with the crane that may require

costly repairs in the future.

When looking for a crane here

are a few aspects of the equipment you’ll want to carefully inspect:

Overall condition

Look for any signs of corrosion to the crane’s exterior that could

indicate a poor preventative maintenance record. Ideally, a crane should be

thoroughly cleaned after each project to keep its components in top working

condition. After examining the overall condition of the crane’s exterior,

inspect the cab to ensure all control mechanisms are operational and fully

intact.

Review preventive maintenance and major component exchange or repairs

Cranes with a history of breaking down have a higher probability of

encountering similar problems in the future. Always take the time to thoroughly

examine all records on the part replacements or repairs on the crane, paying

careful attention to how often the equipment has been serviced over the years.

In addition, reviewing the prior service history of a used crane can

help you estimate possible costs later down the line, helping you to forecast

the number of expenses the equipment more accurately that you may incur in the

months and years ahead.

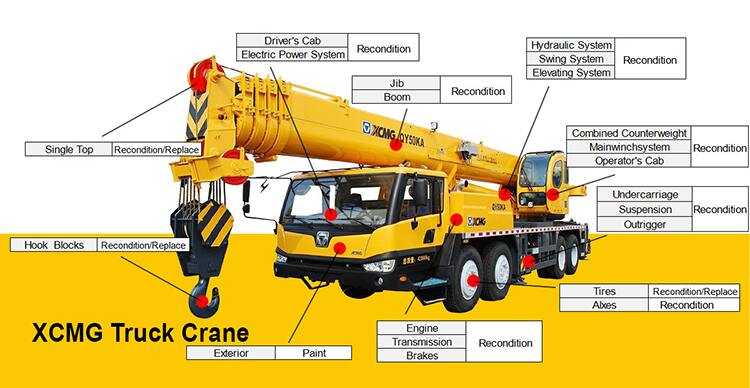

Visual inspection of high wear areas

Pay special attention to visually inspecting parts of the crane that do

the most amount of work. Examples of the high wear components in cranes include

bearings, hoists, wire ropes and braking assemblies. Ideally, these parts of

the crane should be in job-ready condition at the time of purchase.

Be aware that replacing parts on some crane models can take more time

than others. The availability of components is largely determined by the age

and particular model of the crane. To reduce lead time on acquiring critical

crane parts if the equipment needs a

repair, it may be appropriate to order replacement components before the start

of the project.

Leaks

Look for any signs of fluid leaks with the crane. While some leaks are

easy to detect, others may require a closer inspection. For example, the

hydraulic system of a crane may leak internally and show no visible signs of

fluid loss from the exterior. In these cases, the only sign of a leak will be

the crane performing poorly or operating at unusually high temperatures.

Before you buy a used crane, make sure there are no visible or hidden

leaks in the system that could undermine the efficiency of the equipment.

Excessive wear on undercarriage, tires, and other wear components

Check the condition of the crane’s lower body as well, including the

high-wear components of the undercarriage and the tires. If your crane rests on

a crawler chassis, verify that the track shoes and rollers are in good working

order. It’s also important to check the operation of the crane’s turntable,

noting any unusual sounds when rotating that could cause part failure.

Additional wear components to inspect include sheaves, pins, and bushings.

Finding any of these vital parts in poor condition should always merit

immediate repair or replacement.

4. Ongoing Maintenance

Once you purchase a crane, it will need to have required preventive

maintenance and repairs. This is a very important factor when you’re buying an

asset that will be incorporated into your own fleet. Do you have the team and

capacity to service it? A buyer should consider buying a crane from a company

that has an extensive history of ownership and years of maintenance records.

Having a history of that asset and knowing what the next steps are to maintain

the crane in running condition is optimal. Use a company that can pull you an

extensive history with years’ worth of maintenance that has been done to the

equipment.

Choose the Right Used Crane for the Job

A crane is a considerable investment. Knowing what to look for will

help you select the right crane for your company. When it comes to cranes, a

buyer should be educated and feel completely comfortable with their final

decision. At the end of the day, you can buy a crane to work with or you can

buy a crane to work on—if you base your decision solely on price, you might be

getting yourself into a project rather than a machine that’s ready to do the

work.

Machmall.com has the largest fleet of used cranes available today, and

we sell equipment ready for service. Browse through our selection of used

cranes for sale and contact us today to discuss your needs.