How Geofencing and Virtual Fencing Improve Excavator Safety and Performance

Excavators tend to be one of the flagship machines in any construction

fleet. This means that there is considerable interest from the machine owners

and the operators any time that new technologies or features are developed that

promise to enhance a machine’s capabilities.

“Whether it’s road building, site development, underground

utilities—you name it—the excavator is typically the lead machine on the

jobsite. So, the excavator operator is usually one of the more experienced

operators on the jobsite—coordinating this orchestra of work happening around

them,” states Justin Steger, solutions marketing manager for Site Development

and Underground at John Deere.

Given their importance, OEMs have devoted considerable resources to

developing high-tech tools to enhance excavator performance and safety.

One of these tools, virtual fencing, has recently become an

increasingly common feature in controls offerings from the major machinery

manufacturers. Another technology, geofencing, is also quickly gaining

widespread acceptance in excavator circles.

While they may sound similar in name, there is a core, and significant,

difference between the two. Put simply, geofencing is about setting machine

perimeters while virtual fencing is about setting machine parameters.

Virtual fencing allows the operator to program in height, depth, and

width limits on their machine to prevent boom, bucket, arm, cab, or body

overreach. If a pre-determined boundary is attained, an audio or visual alarm

is activated. On some systems, the machine may also be automatically slowed

down.

Geofencing involves programming a “digital barrier” around a machine or

worksite to track movement.

“Geofencing is separate from virtual fencing technology. Geographic

or geofencing is done through telematics. It’s looking at the machine GPS

coordinates for location; where the machine is at,” explains Steger.

“If you put a geofence around your jobsite, and a machine leaves the

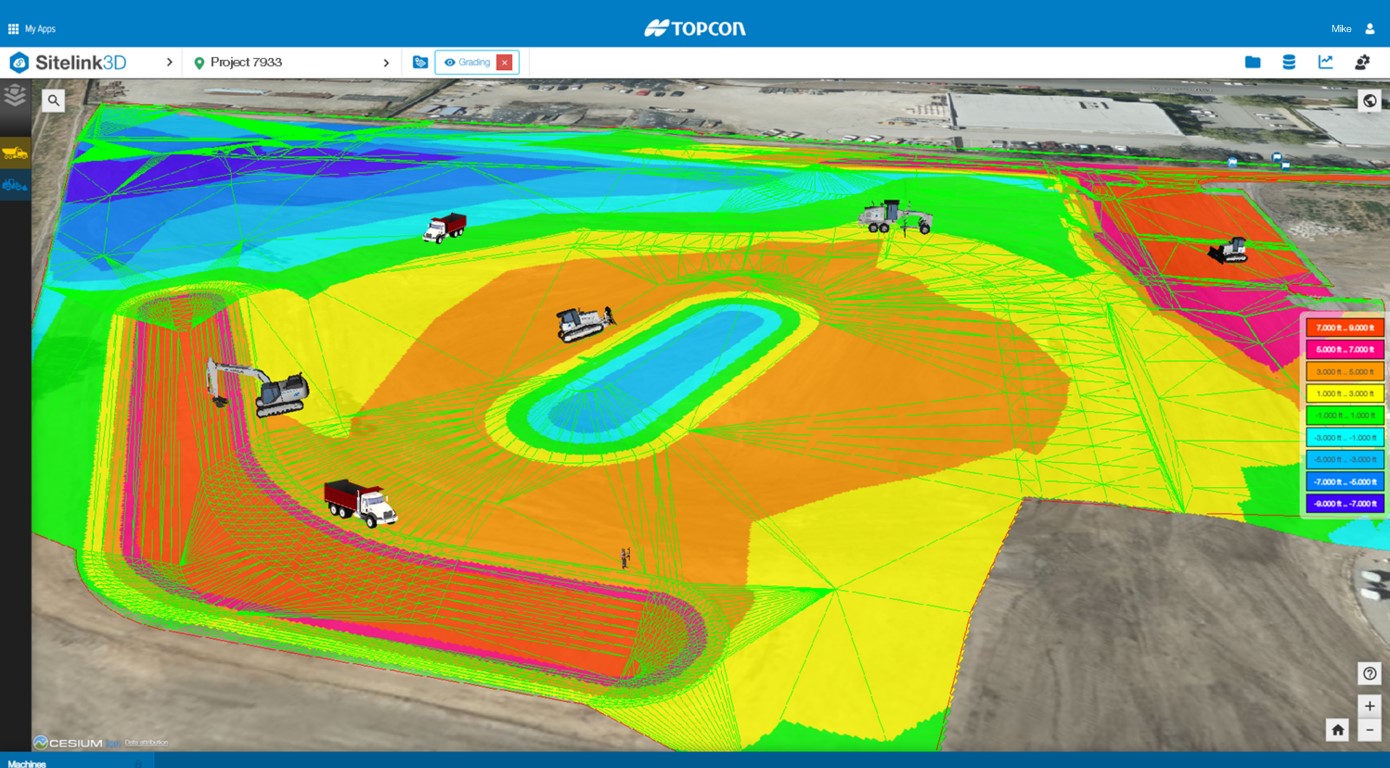

jobsite, the system will send alerts,” explains Mike Wehling, product manager

for Sitelink3D Services at Topcon Positioning Systems, as he outlined the

obvious benefits of geofencing.

“It will also ping wherever that machine is, once outside the

geofence. You will continue to get updated positioning as where the machine

is,” he adds. “If someone is hauling it to Mexico, you’re going to be able to

track it.”

In November of last year, Topcon released MC-Max machine control for

dozers and excavators. Based on the company’s MC-X machine control platform and

backed by Sitelink3D, MC-Max offers automatic bucket and blade control and

remote monitoring capability.