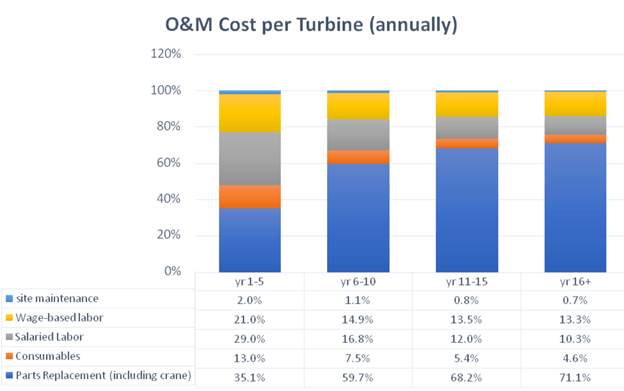

Cranes Cost 50% of Wind Turbine Maintenance Expenses. Here’s How to Reduce That

Ever since its invention to lift water for irrigation 5,000

years ago in Mesopotamia, the crane has been essential for lifting and moving

heavy loads. The Roman empire added treadwheels so a single person could lift

thousands of pounds. The first hydraulic-powered crane dates back to 1838. Now

a wide variety of cranes allow many of the things we take for granted in a

modern society — the type depends on the weight being lifted, the height it

needs to be lifted to, and how long the crane will remain in place.

Fixed tower cranes allow the construction of immense skyscrapers. Robotic

industrial cranes move products and equipment during manufacturing processes.

Horizontal gantry cranes lift and lay sections of bridges and overpasses on

highways and load and unload massive container ships at ports.

In wind energy, several styles of mobile cranes are used,

including crawler cranes, all-terrain truck-mounted cranes and even floating

cranes for offshore installations. Recently, purpose-built wind turbine

assembly cranes have begun to enter the market, hoisting themselves to the top

of wind towers and then lifting the turbine components into place.

As turbines

proliferate and towers grow to sky-scraping heights, cranes will continue to

play an essential role in our clean energy future. Crane equipment and labor

costs make up anywhere from 30 to 50% of the cost of turbine maintenance.

Further innovations in positioning and scheduling these cranes, and in training

the required labor force, can help control these costs.

Two of the primary costs of crane operation are transportation

and downtime. Cranes can be as large as the towers they erect and, depending on

the type, must be dismantled for transportation from site to site. A single

day’s rental can cost anywhere from $10,000 to $50,000, depending on the size

required.

Transporting a crane to the site typically requires 20 or more

truckloads. Each truck can move a load about 600 miles a day, or multiple loads

over a shorter distance. If a crane needs to move 100 miles, it would likely

need a truck to move two to three loads in a day. Mobilization cost can be

almost 50% of overall crane cost for a single turbine repair.

Economies of

scale and careful planning can help to solve this problem. Say a turbine needs

major maintenance every five years, on average, and the maintenance cycle lasts

one week. If used efficiently, a single crane could theoretically maintain 52

turbines per year, or 260 turbines over five years. When large numbers of

turbines — 150 to 200+ — are located close together, a crane can be dedicated

full-time to that site, cutting down dramatically on relocation costs.

On-site labor

downtime can add up as well. Once the crane is delivered, it takes a few days

to set it up, depending on crane type. When maintenance tasks are completed, it

takes another couple days to dismantle and prepare for loading onto trucks to start

the process again.

The crane team and turbine technician team work on different

scopes. Whenever the crane is being assembled, moved or disassembled, the tech

team is idle and more crane personnel are needed. Once the crane is ready to

work, the technicians are working but fewer people are needed on the crane

side. This leads to inefficiencies on both teams; up to 40% of labor costs can

come from idle time.

Cross-training technicians to be proficient in both crane

operation and wind turbine maintenance can be an effective way to reduce costs

and improve the efficiency of the entire process. By eliminating the need for

separate technicians for each task, companies can save significantly on

recruiting and reduce the number of personnel on site.

In addition to the direct savings, cross-training can also

improve the overall efficiency of the maintenance process. Having technicians

familiar with both cranes and wind turbine communication and coordination can

streamline the work and further reduce downtime. And for the wind turbine

owner, this makes the process far easier, as a single contractor can complete

each element of the turbine maintenance process.

However, cross-training technicians can be a significant

undertaking, as it requires time and resources to provide the necessary

education and ensure that technicians are proficient in both areas. Investments

in additional equipment and training materials may be needed. Clean Energy

Services has achieved this in the short term by developing an in-house cross-training

program. For the longer term, CES has partnered with Houston Community College

to develop courses in crane operations and turbine maintenance, ensuring a

consistent pipeline of skilled labor.

Despite these challenges, the cost savings and efficiency

improvements make cross-training crane teams a potentially worthwhile

investment for companies involved in wind turbine maintenance, on top of the

savings to be found for the cranes themselves.