Replacing Crusher Components – What You Should Consider

Many plants have to evaluate whether to do

major component replacements in-house or take advantage of OEM service teams to

complement their site personnel’s efforts. Baden Parker, Senior Manager, Global

Field Services with Metso Outotec, shares his thoughts on what needs to be

considered when dealing with these major service events.

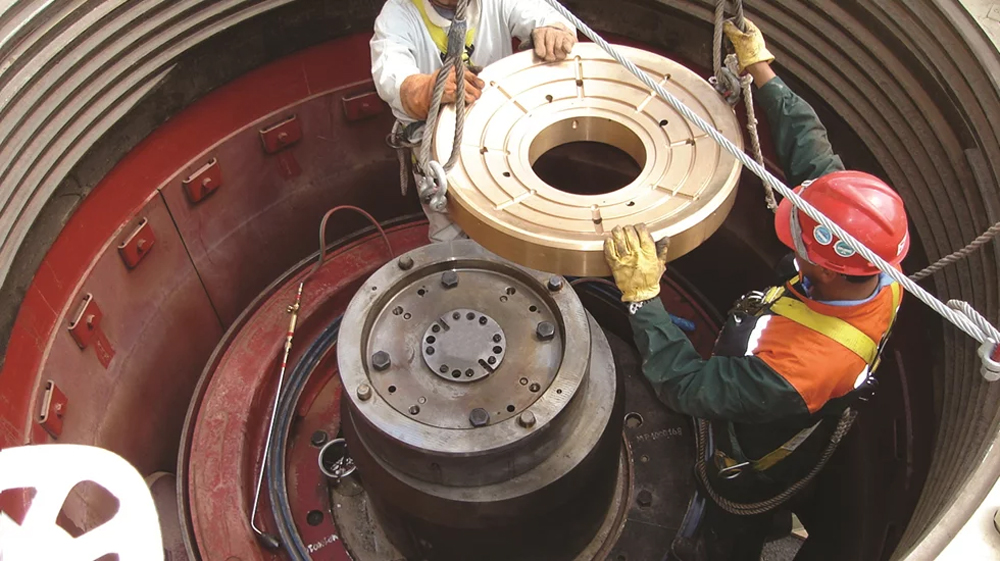

When it comes to replacing major components

for gyratory, cone and jaw crushers, finding the right personnel who are

trained for these specialised tasks can be a challenge. Bottom shells,

mainshafts or gears eventually need replacement or even an upgrade to take

advantage of product improvements. Large and heavy parts often require

specialised handling and installation procedures, as well as specialised tools

to ensure safety.

When replacing an eccentric, a pitman, a

pinion or any other major crusher component, many questions can come up. Has

the site planned this type of work before, and does it have all the right

tools? Are all the service steps perfectly understood to do the work safely and

efficiently? Are there experienced personnel available to execute the part

change-out? Does the site service team know what to look for to make sure the

parts come together properly? Are new parts to be used or are the existing

parts that are going to be re-used in good condition?

Using in-house expertise, OEM support or

both

Many mine sites and plants try to tackle

these types of crusher component change-outs with their in-house capabilities.

However, even with sites that have strong maintenance teams, there are many

challenges that may not be considered. Some sites may have to deal with high

turnover in key service positions, leading to uncertainty in how to perform

these major and non-routine maintenance tasks. Other plants need to service

many models and brands of equipment and may not have the specialised knowledge

that comes from performing complicated parts’ change-outs on a regular basis.

There is also the constant struggle between production and maintenance aims and

goals. When the pressure is on to increase production, there can be the

temptation to shortcut maintenance times, which can lead to equipment problems

or safety concerns that outweigh the time saved doing the actual work.

Having served at mine sites for 10 years, holding roles such as Shift Mechanical Fitter, Leading Hand, Supervisor, Senior Supervisor & Maintenance Planner before joining Metso Outotec as a crusher maintenance expert, has given me a broad view when it comes to service operations. I gained considerable knowledge on the life cycle of a site’s crushing assets and the maintenance required to ensure equipment reliability and, in turn, plant availability. I can say with confidence that if the on-site crews are well trained, many routine tasks can be handled safely and competently. However, a typical maintenance mentality that I observed (and personally held for some time) is ‘We can fix anything ourselves’ and that calling in the OEM was not needed, as we could work out the best ways of working ourselves. For many routine component replacements, this was indeed true enough.

Combining approaches for highest crusher uptime

Having strong in-house site teams

to service crushing and screening equipment can bring many benefits and cost

savings to a plant. However, complementing their efforts by having an OEM

service team either execute or supervise larger, more complicated, or less

often performed component replacements should always be considered and can

bring the best of both worlds. Leveraging OEM know-how for major component

replacement can pay dividends in terms of smoother change-outs and higher

equipment availability due to less issues and rework caused by small missteps.

By utilising Metso Outotec

crusher component replacement services, sites can benefit from the OEM team’s

experience in scheduling and staging pre-outage activities, as well as

executing the work quickly to significantly reduce downtime. It also brings the

advantage of having one point of responsibility for the entire maintenance

event. In some cases, OEM warranties can often be extended when Metso Outotec

crews perform the installation of major parts. With access to global knowledge

centres, trouble shooting and adjustments can often be done on the spot by our on-site

crews, bringing further uptime benefits.