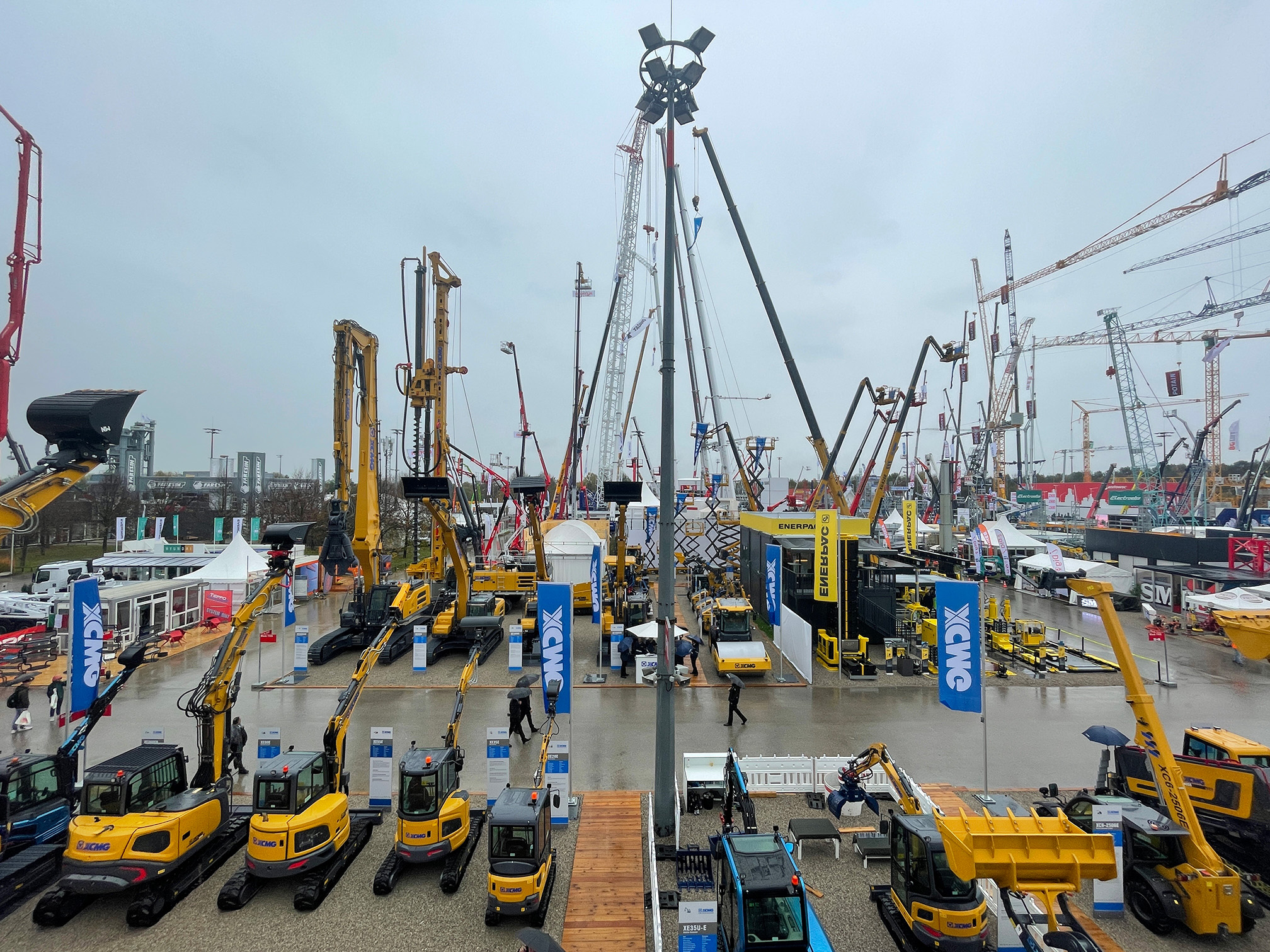

Giant Machines Dominate Munich at Bauma Expo

In the world of

construction, size matters. And in terms of showing off new kit, nowhere is

bigger than Bauma, a trade expo in Munich, Germany.

The skyline above the

614,000 square meters of outdoor and indoor exhibition space is dominated by

cranes, some of which tower well over 70 meters into the sky. The biggest

machines weigh more than 500 tones.

After a three-year

break due to the COVID-19 pandemic, up to 150,000 visitors per day are expected

to join more than 3,100 exhibitors from around 60 countries at the event.

Electric

construction

However, one company

present at Bauma for its 30th year is Chinese manufacturer XCMG. With 41

vehicles on display this year in Munich, its largest-ever fleet in an overseas

market, the company is eager to boost its international clientele further.

"We want to expand our

channel and of course find more dealers and partners," XCMG Group

vice-president Hanson Lu told CGTN. "This year we bring the latest in

innovated new energy machines. It's a lot of electric-driven machines, almost

to cover all – you know like a crane, like an electric driven excavator, loader – this is electric driven, pure electric.”

One of their latest models

being shown to the European market for the first time at Bauma is the 4.2 ton

XE35U-E, designed for landscaping or urban work. It's a purely electric

excavator capable of operating for six to seven hours on a two-hour battery

charge and offers the ability to easily and quickly change buckets to cater for

specific job requirements.

XCMG are dedicated to an

environmentally friendly and sustainable value chain says Hanson, "we say

green production and green product and green logistics. Even our factory is a

green factory. Our roof is all covered in solar panels. That is our main

focus."

Green heavy machinery

Going "green" is

main focus of many manufacturers as much of the industry moves back towards

pre-covid production levels, says Peter Wildemann, the managing director for

Germany at French heavy equipment manufacturer Manitou.

"It is clear like every

manufacturer we are suffering from a lack of components," he says,

referring to the still present COVID-19 logistics and production backlogs

"but every day it comes nearer I would say."

Another concern of many

manufacturers post pandemic is the lack of skilled workers for their equipment:

so many have been turning toward digitization, such as the Italian company

Hydra Robotica, which develops remote operated, eco-friendly robots for

confined spaces.

"If you have a clogged

pipe in the municipality, you do not have to send the operator to clean it. You

would go with the electric robot, with the camera, with the high-pressure pump

and you do the job," Michele Bernini, one of the company's mechanical

engineers and project managers, told CGTN.

However despite all the

efforts towards digital construction sites, autonomous vehicles, alternative

drives and sustainability on show at Bauma - industry experts still cite the

cheaper costs of diesel and lack of reliability for many parts as a main

obstacle to completely computerized and environmentally friendly construction

sites.