Exploring XCMG's Factory Workshop and XCMG Cloud Platform

This morning, CCTV's General and News channels jointly broadcast the program “Morning News,” which took viewers inside XCMG, showcasing their journey towards high-quality development. The broadcast highlighted the stories of XCMG's frontline technical personnel, providing vivid examples of high-quality development in the industry.

Innovation Studio: Where Problems Meet Solutions

In the production workshop of XCMG’s Excavator Division, a particular space caught the attention of the CCTV reporters. This small area, marked by a whiteboard and a few conference tables right next to the production line, is known as the “Innovation Studio.” It's a place where R&D outcomes are validated, and production line challenges are resolved promptly.

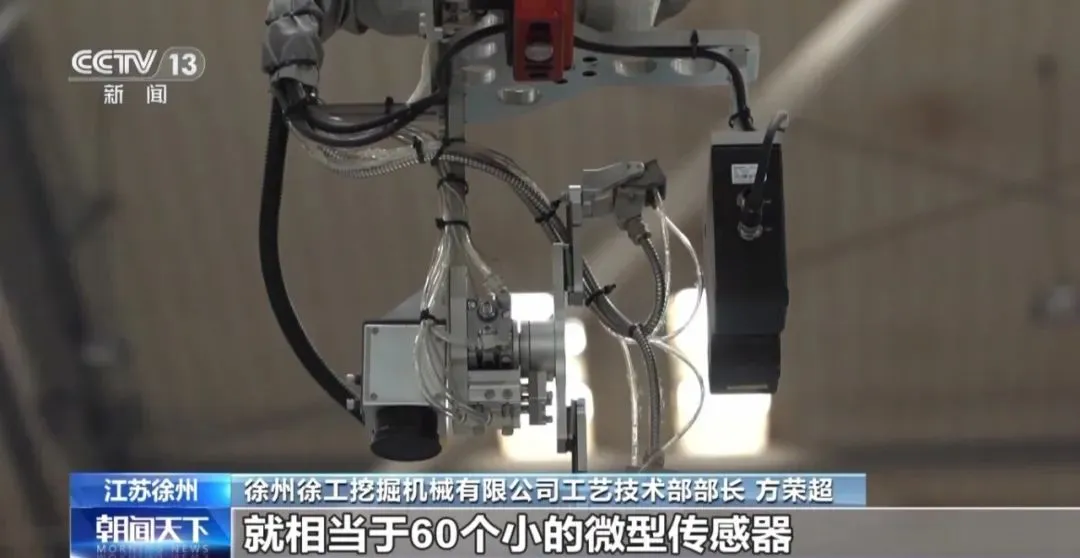

Currently, the studio's team is upgrading a weld seam monitoring system. This new system uses online 3D scanning to intelligently identify defects in the excavator's boom during welding. The core of their innovation lies in a tiny probe, smaller than a palm, which integrates over 60 microchips. These microchips act as mini sensors that can dynamically and in real-time monitor the internal quality of the weld seams. This breakthrough technology has improved inspection efficiency by 120% and raised the defect detection rate from 80% to 100% compared to manual checks.

However, the path to innovation is never easy. At the time, no domestic suppliers were willing to undertake the integration of this equipment. The team conducted repeated validations on hundreds of samples, achieving a fully automated process throughout.

Intelligent Transformation and Flexible Production

Innovation is also evident in the minute details of their operations. The reporters observed that boom arms, differing in weight by as much as 30 tons, are produced on the same production line. Thanks to intelligent transformation, these massive components can now be manufactured with flexibility. Every component has a unique QR code, acting as its "ID card," which ensures orderly assembly. With one excavator rolling off the production line every 8 minutes, production quality and efficiency have significantly improved, filling the team with confidence in their innovations.

Pioneering Digital and Cloud Technology

In XCMG's factory, there are six such studios, continuously injecting vitality into the company’s development. To date, the company has secured over 800 patents. Staff members revealed to the reporters that behind their innovations is robust support from digital technology. Leveraging 5G technology and cloud service platforms, they can monitor and trace the entire lifecycle of a product, from a steel plate to the final assembly.

This year alone, Xuzhou has built 900 new 5G base stations, totaling over 19,500. The XCMG Hanyun Industrial Internet Platform has partnered with more than 70,000 enterprises across over 80 industries. The first step for Hanyun Cloud to connect people, devices, information systems, and the entire industrial ecosystem is to integrate equipment into the platform.

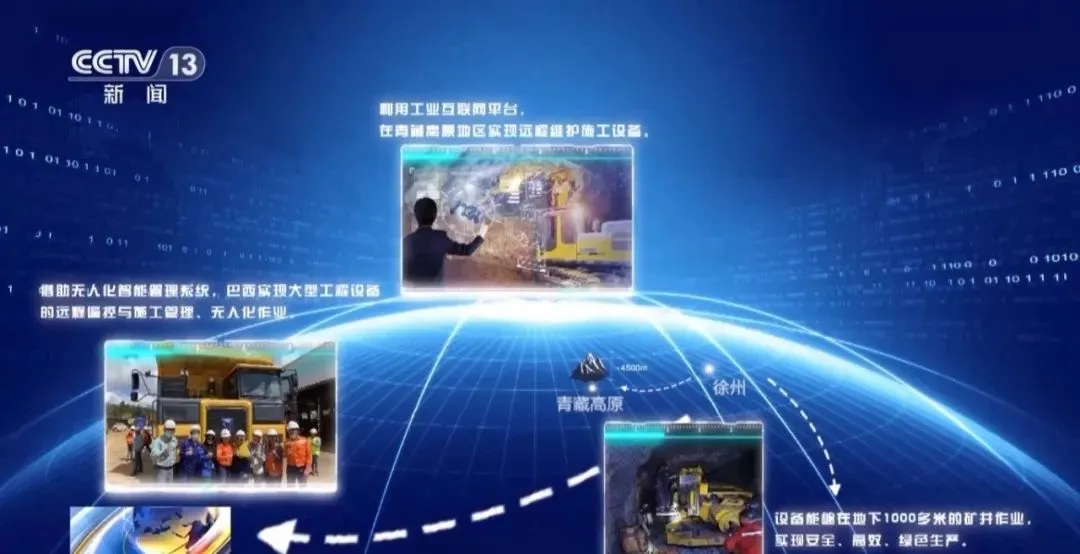

The reporters saw on XCMG Hanyun’s industrial map that the platform’s partnerships extend as far as 18,000 kilometers away in Brazil, as deep as 1,000 meters underground in mines, and as high as the Qinghai-Tibet Plateau. Through big data and AI analysis, the platform can enhance production efficiency for traditional industries and preemptively predict risks to ensure production safety.

Towards Intelligent and Collaborative Systems

XCMG Hanyun has undergone four years of development to provide clients with a smart manufacturing decision-making brain, helping them enhance production and operational capabilities. The next step for this cloud platform is to better serve people, aligning with future trends.

Therefore, they are expanding partnerships beyond manufacturing enterprises to include design firms. On a remotely operated piece of equipment, they harness the advantages of two major platforms. The large screen displayed a video stitching technology, replicating the real effects of operating the equipment. The interactive features include AI-based obstacle recognition and digital twin-based blade posture solutions, helping operators control the equipment more effectively and intuitively.

With the cloud platform, XCMG can precisely understand market and customer needs. From the driving cabin to the smallest button on a component, every aspect undergoes extensive data analysis and experimentation.

Towards a Higher Stage in the Industry

The industry is advancing to a higher level, where construction machinery is evolving from mere tools to intelligent partners, facilitating harmonious collaboration between humans and machines.

XCMG IronPlanet Construction Machinery Auction Event Announcement

XCMG SQS250 truck-mounted cranes are shipped in batches to help infrastructure development along the “Belt and Road”

In the golden 72 hours of rescue, XCMG opens a life channel for the earthquake-stricken areas in Myanmar and Thailand

Chat Now

Chat Now