Current Trends for a More Environmentally Compatible Mining Industry

Good arguments for fewer emissions

Reducing emissions is at the top of the

agenda of the mining sector's environmental goals. “This is where environmental

protection and economy come together in an exemplary manner, as fewer exhaust

gases underground not only serve to protect the climate, but also save costs in

the supply of fresh air,” explains Stöckmann. And what is more are occupational

health and safety aspects. In Germany, for example, new, ambitious occupational

exposure limits (OELs) for nitrogen monoxide and dioxide are to be applied in

the mining industry from November 2021. The OELs for carbon monoxide and

particulate diesel engine emissions will also be tightened.

Heavy-duty truck with overhead line

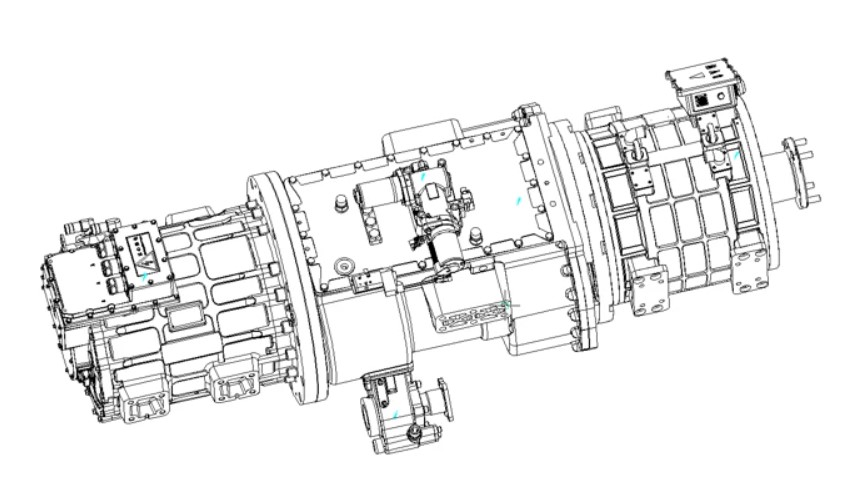

In response to these challenges, mine

operators are increasingly using electromotive drives. For example, at the 2019

edition of the international construction machinery trade fair bauma, Austria's

VA Erzberg GmbH and machine manufacturer Liebherr concluded a development

contract for an overhead line assistance system for a diesel-electric

heavy-duty truck. To date, the world's largest siderite deposit in

Eisenerz/Austria has consumed around 4.5 million liters of diesel per year to

transport 13 million tons of rock. With the new system, it should be three

million liters less in the future, equaling 4200 tons of carbon dioxide.

Battery-electric solutions wanted

everywhere

While cable-connected electric machines

have long been commonplace in the mining industry, battery-powered solutions

have also been in the spotlight for some years now. On the manufacturer side,

Epiroc AB, for example, set itself the goal of offering its complete fleet of

underground mining equipment as battery-electric versions by 2025. The Swedish

machine builder's e-portfolio already includes loaders, mine cars and drilling

rigs. And also users are getting on board with this trending topic. One

example: Rio Tinto, one of the world's largest mining companies, aims to reduce

its absolute emissions by 15 percent by 2030 compared to a 2018 baseline.

According to the company's Climate Change Report 2020, achieving this goal

includes a fully battery-electric mobile fleet.

Best with green electricity

Anyone who is serious about climate

protection must also ask where the electricity used in the machines comes from.

In this context, a growing number of mining companies are testing solar, wind

and battery storage systems at their sites. The report “The Renewable Power of

the Mine", which was published at the end of 2018 and prepared by the

Columbia Center for Sustainable Investment with financial support from German

development cooperation, provides a corresponding overview including many case

studies.

Resource efficient thanks to digitalization

Another aspect of modern mining that is

becoming increasingly important—especially from an environmental point of

view—is resource efficiency. “This is where ecology and economy meet the

trending topics of automation and digitalization,” says Prof. Elisabeth

Clausen. The Institute for Advanced Mining Technologies at the

Rheinisch-Westfälische Technische Hochschule (RWTH) Aachen, which she heads,

develops robust, networked, and autonomous systems as well as smart sensor and

data-based applications for the mining industry. “We want to use them, for

example, to localize and navigate vehicles, recognize people and objects,

characterize materials, and automate and optimize processes,” the expert

outlines.

Selective extraction with environmental

benefits

According to her, one of the main

objectives of the targeted solutions is to extract the respective raw material

as selectively as possible. “This automatically entails ecological benefits,”

the professor emphasizes. For example, digital environment recognition could be

used to continuously analyze the geological structures of the deposit during

extraction. “The better the recognition, the more precise the mining, the less

overburden, the lower the energy consumption during extraction and the lower

the transport expenses,” Prof. Clausen describes one of the environmentally

relevant causal chains. In addition, according to her, sensor and data-based

solutions and technologies can lead to deposits with low raw material contents,

which are not exploitable technically and/or economically today, still being

mined economically in the future—also a step towards higher resource

efficiency.